the combine harvester is no longer a strange concept as its presence is growing strongly worldwide.

Therefore, for agricultural farmers as well as manufacturers,

it is crucial to get thorough information about how the combine harvesters operate,

and the secret of material flow inside these giant machines.

If they are the knowledge you are looking for, then the information presented below will not disappoint you.

The following article is going to unveil the Working processes of combine harvesters

and contains useful discussions about technical issues.

Overview of Combine Harvesters and Working Processes

Together with the development of science and technology,

combine harvesters were built for the mission of facilitating and simplifying the harvesting process.

For that reason, combine harvesters have become multi-task machines,

to boost harvesting efficiency and enhance convenience.

These indispensable harvesting machines execute certain main tasks, namely crop cutting, threshing and grain cleaning.

Some crops commonly harvested by combine harvesters include wheat, rice, barley and so forth.

There is no doubt that modern combines can be used for a vast number of crop types at different terrains from plain to hillside areas.

Defined by working mechanism, combine harvesters are divided into controlled and self-propelled ones.

Besides their familiar presence on the field, a combine can run on public roads to the target destination, which is extremely mobile.

After the main processes, clean grains are conveyed into a combine tank and then carried to a grain elevator.

Meanwhile, the material-other-than-grain (MOG) mixture is blown away from the combines.

Notably, the combine harvester is integrated with all technological operations of grain harvesting:

cutting and gathering of the plants, grain threshing and separating, and grain cleaning and collecting in the combine tank.

Though there are different designs of combine harvesters for different grain crops’ conditions, they all follow the above-mentioned functions.

So, let’s take a look at the specific working processes of combine harvesters as follows.

However, before jumping into the specific working mechanism, you should get yourself more familiarized with this special machine – combine harversters.

Combine Harvesters’ Processes of Grain Cutting and Gathering

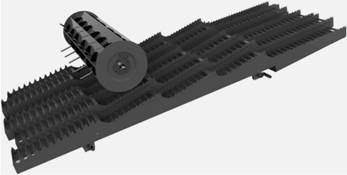

The combine harvester is built with a header to cut and gather all kinds of crops.

This header is designed to be interchangeable,

so that it can execute the cutting and gathering processes of many kinds of crops with different grain types and harvesting technology.

The header is mounted in the front of the combine, usually compatible with the combine width.

However, different types of headers are found in different designs,

because the harvester can have a faster and more efficient cutting process with a wider header.

The crops are pushed down by a rotating wheel called the reel and guided to the cutter.

The reel’s horizontal bars named bats, together with vertical teeth, grip the plant stalks.

The header is also equipped with the dividers,

to divide the crop that the machine is going to cut and the rest of the crop that is gently pushed,

to prevent the remaining part from being damaged.

The cut crops are directed to the pan of cutter bar that goes along with the header underneath the reel.

The cutter bar has an auger whose left and right hand screws help direct the material toward auger’s centre.

The intake auger is combined with a retractable-finger drum to push the gathered material into a combine feeder-house.

For different purposes, a grain header may have several enhanced or supplementary attachments,

namely flexible floating cutter bar, full-width retracting fingers, headlights, full-fingered intake augers, extendable platform, different knife-guard combinations, side cutter bars or an extended platform for rapeseed harvesting.

All of these bring about a better process of cutting and gathering the crops.

Combine Harvesters’ Processes of Grain Threshing and Separating

Following cutting and gathering stage, the crops are transferred to the processes of threshing and separating.

These processes’ functions are detaching the grains from the flowery cover and separating them from the MOG.

The threshing process is run by a threshing unit mainly consisting of a rotary threshing drum known as a cylinder or and a concave.

Generally speaking, threshing system cannot totally separate all grains;

therefore, the combine harvester is constructed with straw walkers to take the remaining grains out of the straw.

In the threshing unit, a rotary threshing drum smashes the crops to get the grains from their stalks.

The threshed grains pass through the concave to the grain pan.

It is noted that the threshing drum’s speed must be easily modified to widely apply for the threshing processes of different crops with different conditions and characteristics.

At the same time, the distance between concave and drum can also be adjustable for various crops’ requirements.

The MOG and unthreshed grains pass along the straw walkers toward the walkers’ end. In this so-called separating process,

the material is rethreshed and mixture of remained grains.

Short straws and dust particles fall into step bed through bottom pam of straw walkers.

Subsequently, the grain and some trash material come to cleaning unit of the combine harvester and the successive process is in charge.

Combine Harvesters’ Grain cleaning and collecting

Now the threshed grains from the threshing drum, the re-threshed grains from, the straw walkers together with short straws and other small particles pass through the cleaning unit.

The cleaning unit generally includes a grain pan, two sieves, and a fan.

The top sieve has size-adjustable openings while the bottom sieve is changeable for different crops.

The strong air current directed from blower blows all the chaff, straw fragments, and dust particles away while the grains fall through the openings of the sieves.

In particular, the separated MOG is discharged at the end of the machine, sometimes with a spreader to fasten the straw release.

Meanwhile, the clean grains are collected into the combine tank.

When the combine tank is filled with clean grains, they are carried up by an elevator and delivered into the trailer.

Combine Harvester and Inclination Issues

While conventional combine harvesters usually run on the fields with a maximum 6% of hillside slope and 8% slope for the longitudinal direction,

the actual hillsides’ slopes can reach up to 45%.

Therefore, leveling the combine body not only enables the straw walkers to work properly but also helps maintain the machine federate.

If separating units are appropriately levelled,

the machine’s center of gravity is repositioned relative to the base area that is defined by the position of the wheels.

This solution increases the stability of the machine and prevents collapsing.

Due to the diverse terrain types,

the best hillside combine harvesters should be equipped with both transversal and longitudinal leveling with these inclinations:

transversal slopes of up to 42%

downhill slopes of up to 12%

uphill slopes of up to 30%.

Although this combine’s parameter has decreased,

the newly-designed combine harvesters built with axial rotary threshing and cleaning units can operate well on transversal slopes of up to 20% to improve the stability.

Technological Requirements for Combine Harvesters

Combine harvesters have been playing an integral role in agricultural activities and labor-saving innovation.

As a result of the wide application in various farming areas and conditions,

harvesters need to be equipped with modern technology to execute multi-tasks in a flexible manner.

So, let’s see how they are so important and what the technological requirements are:

-

The machine is regarded as the major harvesting technology worldwide.

-

It harvests the crops at the right moment with minimal grain losses, sustaining crop quality.

-

The combine can lift the plants that fall off due to the bad weather, execute cutting, threshing, and cleaning processes properly inside the machine. Otherwise, there may be a huge loss of grains with traditional harvesting.

-

The combine’s equipment or subassemblies can be modified for particular crop harvesting, bringing about a better quality and quantity of grains.

-

The machine’s speed is adjustable according to the crop conditions, while the process parameters remain the optimum values. That means there are separating power transmission channels from the same engine.

-

High harvesting efficiency results from the proper machine operation, in which machine monitoring and controlling make a huge contribution to this improvement.

-

The operator comfort in an optimally controlled cab is remarkably taken into consideration for machine design, manufacturing, and operation.

-

The increase in combine feedrate stems from two essential requirements: optimizing the crop production and the harvesting necessity within optimal harvesting time periods.

-

It is the fact that the self-propelled combine harvesters have reached the road’s limiting width. Therefore, modeling, simulation, and optimization of both processes and component design will help achieve a continuous improvement of combine harvester performance.

-

The operation rate of combine can also be promoted by fully and continuously harvesting crops without switching between different fields. Trailers are sufficiently provided for grain unloading and a proper storage, drying or post-harvest processing capacity is indispensable.

Conclusion of Combine Harvesters’ Working Processes and Technical Issues

The above information has provided you with a thorough view of crop flow inside the combine harvesters and major working processes: cutting and gathering of the plants, grain threshing and separating, and grain cleaning and collecting.

Understanding these processes can help you further deal with your concerns or just satisfy your curiosity about this machine.

At the same time, some problems have also been discussed from the technical point of view. We hope you enjoy our article and see you at other useful writings as well!

If you want to go further into knowing the detailed composition of a combine harvester, from its header to its functioning units, you can read our other articles.

We highly recommend you start with the foremost component: combine headers, to have a more systematic and sequential knowledge.

Link out and prosper!