Meta: Combine concaves are the secret behind the top-notch grain quality of a combine harvester. But, what exactly are they? This article will address the issue.

Combine concaves play an integral role in threshing and separating grain, affecting the operation efficiency and grain quality, contributing to the overall performance of combine harvesters.

As its name suggests, combine harvesters merge the harvesting operation into a single process: from plant cutting and gathering, grain threshing and separating, to grain cleaning and collecting in the combine tank.

After endless times of upgrades and improvements, the combine concave has become sophisticated, making it an indispensable component of combine harvesters.

This article will help you address the following questions:

- How do combine concaves work?

- How are they classified?

- What is noteworthy about combine concaves?

These questions may confuse people with limited understanding about this kind of component.

But don’t worry, as you will find all your answers right here in this article.

Let’s explore together!

Basics Of Combine Concaves

It is commonly known that combine concaves are a component of the threshing unit.

Particularly, the threshing process’s main role is detaching grain from the plants and flowery cover such as panicles, ears, cobs, pods, and so forth.

This operational task is implemented thanks to a series of phenomena generated from the impact and centrifugal forces, friction caused by mechanical action, and friction due to the collision of the components of the ears.

In terms of structure, a threshing unit is mainly composed of a rotating cylinder or rotor, rasp bars, and a concave or cage.

The combination of these components generates impact forces on the crops fed into the threshing unit that will eventually separate grain through the openings of the concave.

Apart from this brief introduction, we also have a more detailed article describing the threshing unit in combine harvesters.

Purposes Of Combine Concaves

Generally speaking, the harvesting process is long, complicated, and involves a variety of activities.

The main tasks include reaping, stacking, handling, threshing, cleaning, and hauling.

All of these activities have to be done systematically to obtain the best performance.

No matter what the combine harvester is, the concave always plays an indispensable role in the quality of the crop harvested.

In fact, the concave is aimed at improving the quality of the harvest.

Particularly, the combine concave executes two essential functions that are threshing and separating.

- Threshing is involved in freeing the seeds from the plants.

- Separating, as the name implies, executes separating the seeds from the chaff.

Advantages Of Using Combine Concaves

As mentioned earlier, the concave is involved in two essential processes of harvesting.

Also, the type of concave used determines the quality of the harvested crop.

There are multiple benefits of using a combine concave.

The modern combine concaves are highly efficient and continuously being upgraded.

Some of their advantages are listed below:

- The concave can be utilized for harvesting a wide range of crops.

- This device has better durability than most of its contemporaries, making it outlast longer.

- The crop’s productivity can be maximized by applying different fixtures in the concave.

- The concave ensures safety and high fuel-efficiency.

- The device is reliable, affordable, and needs no repairs or alternation for a long period of time.

How Combine Concaves Work

In general, the friction among the threshing drum, also called the rotating cylinder, the crop fed into the threshing space, and the concave create the threshing process.

When the crop comes in the threshing unit, it gets smashed by the cylinder against the concave, and grain starts to pass through the openings of the concave.

Therefore, the grain is separated from the straw.

It is worth noting that the concave sections must be interchangeable for harvesting different crops because their grain and stem sizes, together with their mechanical and aerodynamic properties are different.

The grain’ s cleanness level is determined by a series of factors that are the clearance distance, the speed of the rotor, the bar and wire patterns of the concave, and the crop types.

Concaves’ Working In Tangential Threshing Units

In tangential threshing units, the clearance between cylinder and concave is larger where the material comes in the threshing space, and it is smaller at the escape.

The clearance distance is calculated radially from the point of the outside diameter of the cylinder to the top surface of a bar.

The ratio between the values of the clearance at the entrance and the exit of the threshing space is 3-5.5 in cereals and beans and 1.8-2.5 in corn.

The concave’s shape is like a curved grill, wrapping the cylinder over a certain center angle.

The concave may consist of more sequential sections relative to the feeding zone, threshing and separating zone, and release zone of the material-other-than-grain (MOG).

The threshing and separating zone of a concave largely comprises lateral supports, intermediate curved bars, and reinforcing rods that are oriented toward the movement direction of the material.

The bars are considered as the major active elements of the concave.

Concaves’ Working In Axial Threshing Units

Different from the concaves in tangential threshing units, concaves in axial threshing have other particular features.

A rotary threshing unit requires a raised power and releases a higher degree of MOG fragmentation and separation through concave and cage openings, resulting in overcharging the combine’s cleaning unit.

It is noticeable that the combine’s cage is fixed; meanwhile, the concave underneath the cage is constructed with three or four interchangeable, adjustable sections for executing tasks with different crops in diverse field conditions.

Types Of Combine Concaves

Based on the research of Loewen, combine concaves are divided into a variety of common types according to their using purposes and designs.

For particular purposes and crop conditions, concaves are equipped with different types of bars and wires.

Commonly, while the concave’s straight bars run parallel to the rotating axis, the curved wires are perpendicular to that direction.

The arrangement and distance of bars and wires depend on the crop types.

For example, narrow-wired concaves are suitable for small grains such as wheat and barley since the small seeds can pass through the narrow spacing between wires.

Meanwhile, the wide-wired concaves are used to separate the grains like corn or beans.

The wide-wired concave’s design is similar to that of narrow-wired one but has larger spacing between the wires.

Therefore, this section is targeted at revealing a thorough view of different types of combine concaves.

Along with the diversity in models and variants of combine harvesters, different concaves are designed to suit the operational talks and specific purposes.

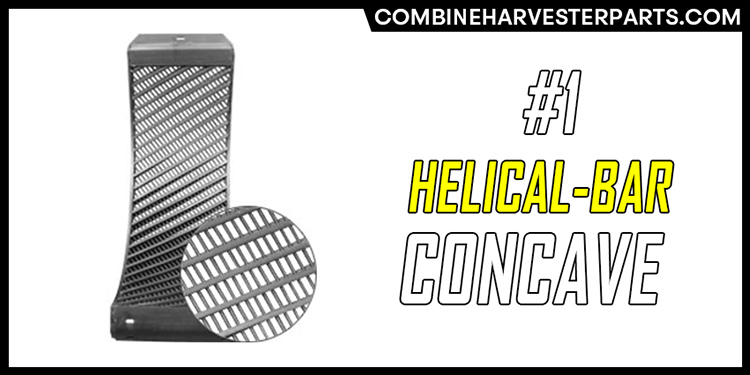

Type #1: Helical-Bar Concaves

The helical-bar concave is often used when there is a requirement of aggressive threshing.

Because the crossbars and wires shape a diagonal direction, the material coming in the rotor strikes a helical-bar concave at a right angle.

With this solution, the whiteheads and unthreshed grain can be prevented.

This ingenious concave can be positioned in the front concave where the tough threshing grain comes in.

Besides, the middle concave can be substituted with a helical-bar concave if there is a need for more aggressive threshing, based on the crop conditions.

This innovative concave is suitable for separating the small grains.

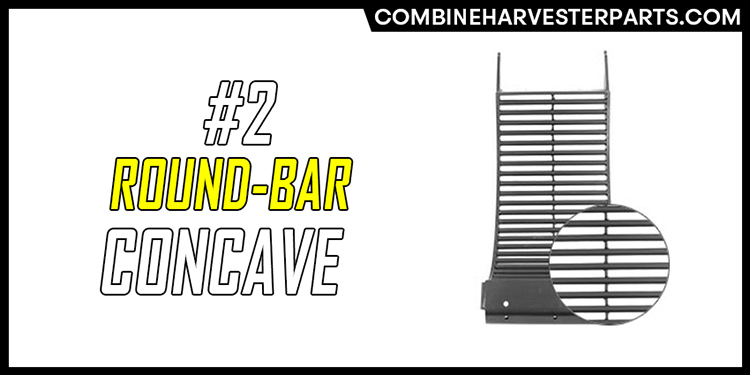

Type #2: Round-Bar Concaves

The round-bar concaves have round crossbars and feature no wires.

This design is different from the square-edged bars of the wide, narrow, and helical concaves.

The round-bar concave is appropriate for harvesting field corn, popcorn, soybeans, and food corn.

It is also a recommended choice for small grains, sunflowers, sorghum, and canola when combined with a helical-bar concave in the front.

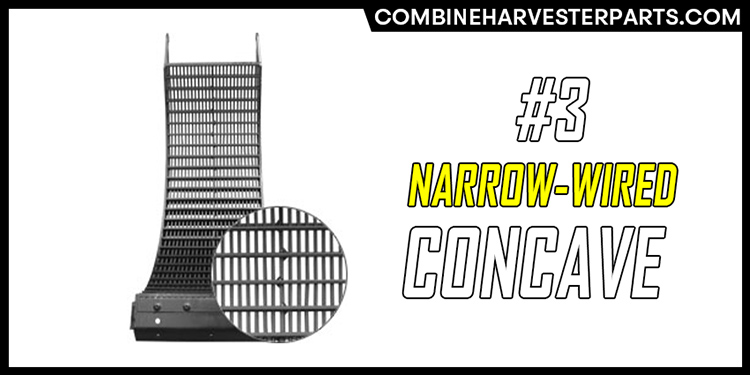

Type #3: Narrow-Wired Concaves

The narrow-wired concaves can be seen as a standard option for small grains such as wheat, canola, oats, and barley, as well as other cereal crops and fine seeds.

The wires run perpendicular to the heavy-duty crossbars, and are spaced just wide enough so that the small grains can fall through the concave.

At the same time, this design allows the chaff to move toward the end of the combine. This kind of concave is not suggested for use in corn.

Type #4: Wide-Wired Concaves

The wide-wired concaves are designed for harvesting corn, soybeans, and other large grain crops such as sorghum, rice, and sunflowers.

This concave is equipped with wires perpendicular to the strong crossbars, which is similar to the narrow-wired concave in general design.

However, the gap is wider, allowing more space for larger material to be smashed, and for the larger grain to fall through the concave without blocking.

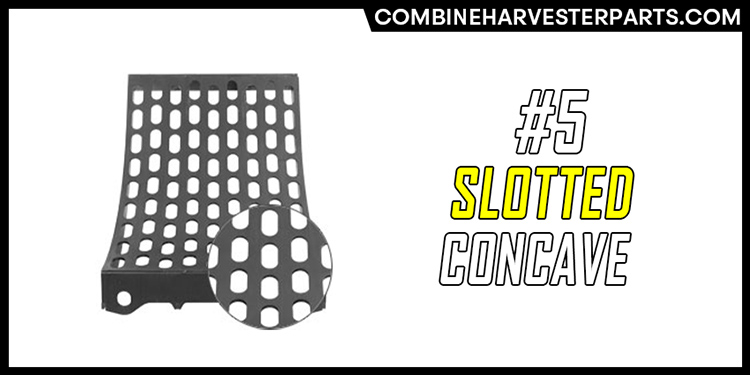

Type #5: Slotted Concaves

The slotted concaves are designed with a smooth surface, reducing the crop damage, and improving the feeding.

This concave is suitable for harvesting corn and bean crops.

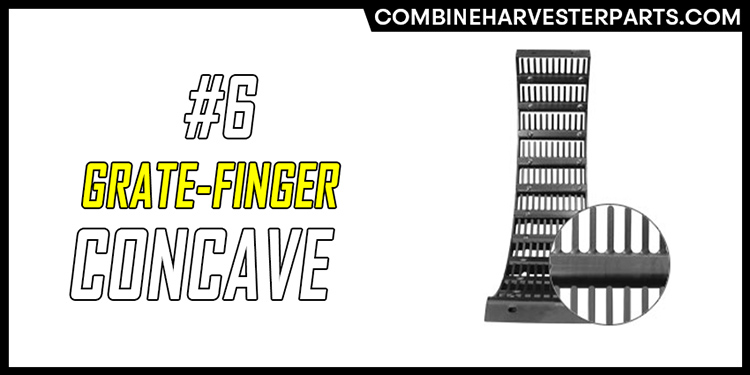

Type #6: Grate-Finger Concaves

The grate-finger concaves are fabricated from the laser-cut steel, bringing about greater durability and less ability of wear and breakage.

The concave is also changeable in terms of individual finger sets.

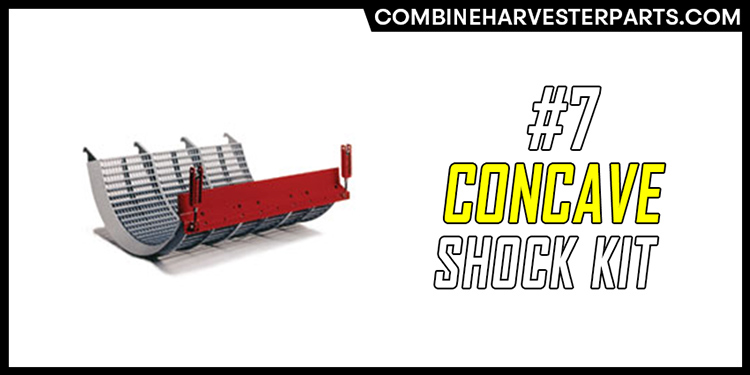

Type #7: Spring-Loaded Shock Kits

The spring-loaded shock kit’s advantage is minimizing and preventing damage to concaves, pipes, and rotors.

In the working process, the shock, which is generated from the foreign objects or a large loading of material passing through the threshing space, is absorbed by the heavy-duty compression.

Suitable Settings For Combine Concaves

After continuous trials and improvements, the combine harvesters have satisfied their users – the farmers in the fields.

The perfection has been bestowed upon the threshing system that now performs excellently under any circumstances.

Therefore, it is crucial to understand the function of the concave and how the optimized combine concave setting can strengthen the performance of the harvesting machine.

Choosing the best combine harvesters with top-notch concaves gives the farmers an efficient operating process.

So, let’s look at the following setting recommendations.

Minimize The Rotor Losses

Regarded as one of the most challenging factors for farmers, rotor loss is worth being taken into consideration.

In fact, rotor loss appears in all machines, so the farmers need to make sure the rotor loss is minimized in their combine harvesters.

The rotor loss in the combine will be up to 2 – 5 bushels per acre, which is equivalent to $32,000 per 1000 acre of soybeans.

In case you can seek the best concave system, it can help limit these losses through the working process.

Opting For The Setting For Each Crop

Properly setting combine concaves makes a remarkable contribution to the performance enhancement for various crops, including wheat, corn, lentils, sorghum, ax, chickpeas, pinto beans, soybeans, canola, kidney beans, and black-eyed peas.

Before starting to harvest the crop, it is necessary to adjust the setting on the machine since each type of crop requires a different setting to achieve the best result.

These adjustments can enable the farmers to get a larger threshing area.

Pay More Attention To High-Moisture Crops

On average, 200 acres of crops will be harvested by a combine harvester on a hot and dry day.

It executes three operations simultaneously: reaping, threshing, and winnowing.

If the farmers are harvesting high-moisture crops, it is necessary to set up the bottom sieve to achieve the largest clearance between the concave and the rotor, or just take it out. Instead, a high-capacity top chafer can be utilized.

The next step is controlling the ground speed to decrease the losses.

The purpose of the clearance is to regulate the flow of the material, and clearance setting will depend on the size and other characteristics of the grains.

Prioritize Best Operation Conditions Of The Harvesters

Actually, investing in a high-quality concave is definitely a profitable business, and it will pay back for the users in time.

It is recommended to pick one that is adjustable to be flexibly manipulated for different crops.

In fact, if the farmers can utilize the same concave for all crops, they can save time and effort, leading to an increase in efficiency and profitability.

It is required to have the appropriate setting on the concave so the losses are cut and profits are extended.

Impacts On Performance Of Combine Concaves

A lot of resources, effort, and time are invested for crop growth; thus, everything needs to cooperate well with each other to get the best output.

It is not exceptional for researching all problems affecting combine concaves and finding ways to solve them. Here are listed problems that combine concave manufacturers need to cope with.

Cutting And Feeding

Cutting and feeding can affect the work of combine concaves due to their direct mutual interaction.

The common problem during this cutting gathering process is the material flow supplied for the threshing unit, which sometimes makes the concave overloaded or ineffective.

The combine concave manufacturers should pay attention to regulating the flow of the crop from the header into the feeder house.

A smooth feeding process helps optimize the work of the concave and threshing unit.

Threshing And Separating

A typical issue in the threshing process stems from not all plant material being smashed.

This can originate from the work of the cylinder or the rotor, and the uneven harvesting flow from the header.

Therefore, it is necessary to ensure the platform feeds appropriately, and the cylinder works properly.

Also, the clearance between the concave and the cylinder inflicts a huge impact on the grain separating quality.

It will be best if this clearance is suitable for the flow of the material and the combined force put onto the material as well.

Factors To Choose The Right Combine Concave Manufacturers

It is sometimes tricky to choose the suitable and reliable combine concave manufacturers due to a vast number of advertisements.

An appropriate combine concave manufacturer is the one whose products best suit the customers’ requirements.

There are multiple factors to be assessed, but some of the most important criteria are suggested as follows:

- A combine concave is a modification that is added to the current harvesting machine. Therefore, it is vital to know the machine’s model, which is being used. This step helps the customers in understanding what type of modification suits the machine the best.

- A combine concave is mainly involved in threshing and separating the crops. At the same time, using a combine concave contributes to enhancing the quality of the crops, thus choosing the appropriate model is indispensable. To obtain this goal, it is necessary for customers to do adequate research about the product and the combine concave manufacturer, making your decision more accurate. Besides, the customers can read other people’s reviews to have a multi-dimensional view. Last but not least, comparing all the shortlisted combine concave manufacturers to decide the most suitable one.

Conclusion

Combine concaves contribute significantly to the harvesting process of combine harvesters. The component directly involves threshing and separating the grain from the plant and chaff.

Combine concaves are now widely used since they are suitable for a wide array of crops.

The indispensable part also improves the quality of your harvest.

The discussion above helps bring about a clear picture of combine concaves’ structure and working mechanism in different threshing designs, together with specific types of concaves for particular crops.

Furthermore, it is useful to get aware of the proper setting for combine concaves before coming to work on the fields.

It is also necessary to clearly understand the impacts on the performance of combine concave together with the criteria of an appropriate combine concave manufacturer.

Combine concaves are always the components of interest for farmers, manufacturers, or those who wish to thoroughly understand combine harvesters.

We hope the information is beneficial for you and may deal with your concerns about combine concaves.

For further discussions related to combine harvesters, please find us in other articles.

Frequently Asked Questions On Combine Concaves

This section will clarify all your common questions about combine concaves. Stay tuned for many detailedly brief explanations right here.

References

- Concave on Combine Harvester – Everything about it. Thanh Trung. Retrieved June 02nd, 2021.

- Concaves. Loewen Manufacturing. Retrieved June 02nd, 2021.

- Miu, P. (2015). Combine Harvesters: Theory, Modeling, and Design. CRC Press.