Meta: Combine harvesters are iconic figures of modern agriculture. How do such machines simplify farming tasks and increase productivity? The answer is right here!

Combine harvesters are regarded as the synonym of modern agriculture. It not only transforms the manual farming tasks into a more industrial procedure but also offers top-notch efficiency to farmers.

That is why I dedicate this whole article to cover everything there is to know about combine harvesters.

- Fundamental information about combine harvesters (definition, classification, working process, structure)

- Most up-to-date data about combine harvester market (in India and Vietnam).

- Top 04 biggest manufacturers of combine harvesters.

Let’s dive right in.

What Is A Combine Harvester?

Combine harvester is a multi-functional machine for crop harvesting.

Combine harvesters can gather over 80 different types of crops (wheat, corn, soybeans, sunflowers, barley, clover, etc.)

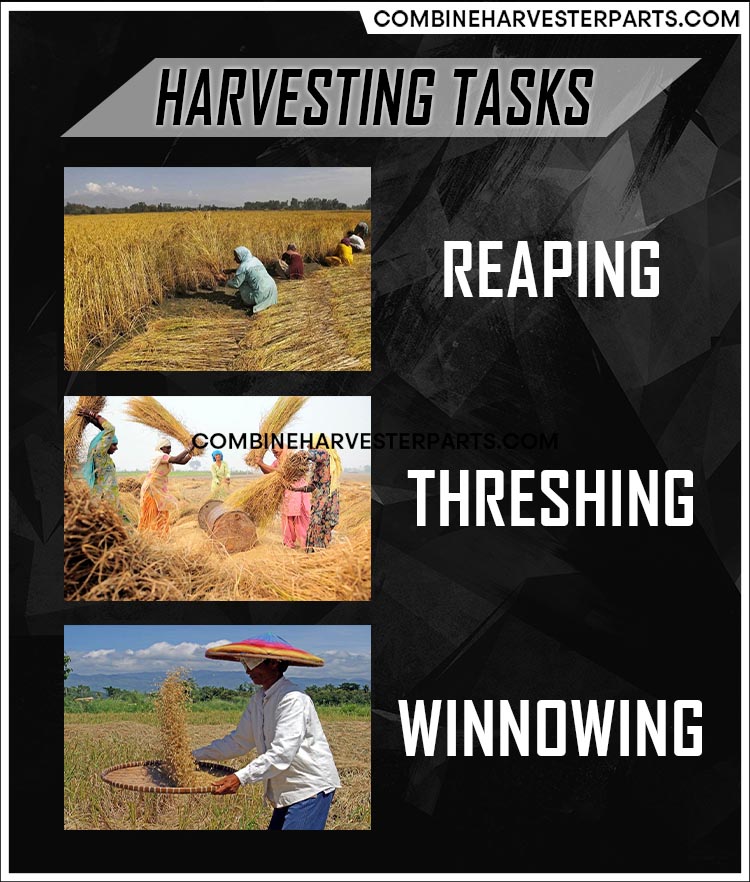

The word “combine” refers to the combination of three sequential tasks in the harvesting activity:

- Reaping: means cutting or gathering crops (like rice fields)

- Threshing: means the beating and separating the seeds from stalks

- Winnowing: means the freeing of grain from lighter particles (chaff, dirt, etc.)

Combine harvester is one of the most important inventions in farming. The machine helps reduce the amount of people engaging in agricultural works.

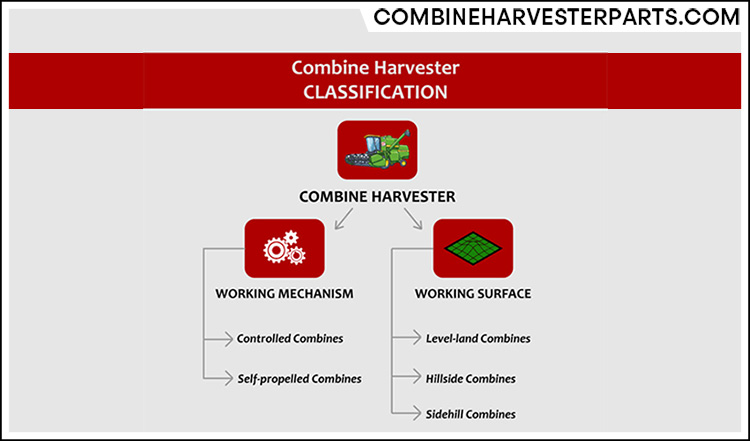

How To Classify Combine Harvesters?

This part will help you explore:

- Two ways of classifying combines: based on working mechanism, and on working surface.

- Quick comparison within each classification.

Classification Way #1: Based On Working Mechanism

We can divide combine harvesters into two main groups:

- Controlled combine harvester

- Self-propelled combine harvester

Controlled Combine Harvesters

Controlled combine harvester refers to machines manually operated by an operator. Its other names include: tractor-pull combine, tractor combine, and pull-type harvesting combine.

Nowadays, this type of combine harvester is NOT widespread. Thus, we will NOT go into much detail about it.

Self-Propelled Combine Harvesters

Most combine harvesters you see on the field today are self-propelled combine harvesters. They run by themselves with an engine attached above. The engine power plays two roles: driving and harvesting operations.

Whenever we use the word “combine harvester”, we refer to self-propelled combine harvesters.

Within self-propelled category, there are two subtypes:

- Conventional combine harvesters.

- Rotary (axial-flow) combine harvesters.

The following table offers a quick comparison between conventional and rotary combine harvesters.

Table 01 – Brief matchup between

conventional and rotary combine harvesters

| Conventional

Combine Harvesters |

Rotary

Combine Harvesters |

|

| Similarities | The operator’s RIGHT setup is important to bring about HIGH output quality. |

|

| Differences | ||

| Moving Parts | More | Less |

| Durability | Less | More |

| Prone To Breakdown | More | Less |

| Capacity | Less | More |

| History | 19th century | Since 1975 |

Classification Way #2: Based On Working Surface

We can divide combine harvesters into three main types:

- Level-land combine harvester: refers to machines working on even surfaces.

- Hillside and Sidehill combine harvester: refers to machines working on steep surfaces (like a hill)

Hillside and Sidehill combines can be confusing. But do not worry! As I will clarify them below.

Similarity of Hillside and Sidehill

Same function of balancing the combines on steep hills.

- The shift in the combine’s center of gravity helps prevent the risk of being rolled over.

- Without this function, chaff and grain would jump to one side of the machine, and lower threshing efficiency.

Differences of Hillside and Sidehill

Hillside combines can work on steeper conditions.

- According to Wikipedia, Hillside combine harvesters level around 35% on average (older models can reach up to 50%).

- However, Sidehill combine harvesters only level to nearly 18%.

Hillside combines leveled BOTH front-to-back and side-to-side, whereas Sidehill combines leveled ONLY side-to-side.

Hillside combine’s designs are higher.

- It requires additional 2-5 feet of steel on top.

- This higher structure provides smoother rides for operators.

Three-Step Working Process Of Combine Harvesters

In this part, we will go step-by-step into:

- Three stages of the combine harvester’s working process.

- Learn about the activities in each stage.

Step #1: Reaping The Plants

The working process begins with the reaping activity. This task is carried out by the combine header, which is mounted at the front of the combine harvester.

There are various types of headers, specifically designed for particular crops. During operation, the header gathers grains into the combine.

Step #2: Threshing And Separating Plants

Then, grain travels up a conveyor to the threshing unit of combine harvesters. Here, the threshing drum beats the crops to break against the combine concave.

After that, the broken crops come to the separating unit of combine harvester (next to the threshing unit) for separation grains away from their stalks.

The grains then fall through the sieves and land into the collecting tank. The unwanted material (chaff and stalks) passes along straw walkers toward the back of the machine.

Step #3: Winnowing Grains And Discharging material-other-than-grains (MOGs)

As the collecting tank fills up, it must be emptied into a trailer through a pipe unloader (or side pipe).

The grain is elevated from the tank by an elevator and shoots out of a side pipe into the trailer. The trailer is usually attached to a tractor and goes side-by-side with the combine harvester.

Grains are then delivered to the cleaning unit of the combine harvester.

One by-product from this working process is the material-other-than-grain (MOG), which include remaining leaves and stems with limited nutrients.

Certain combines have a rotating spreader mechanism that throws the MOGs over a wide area. MOG is discharged on the farm, or baled up for bedding and livestock.

Structure Of Combine Harvesters

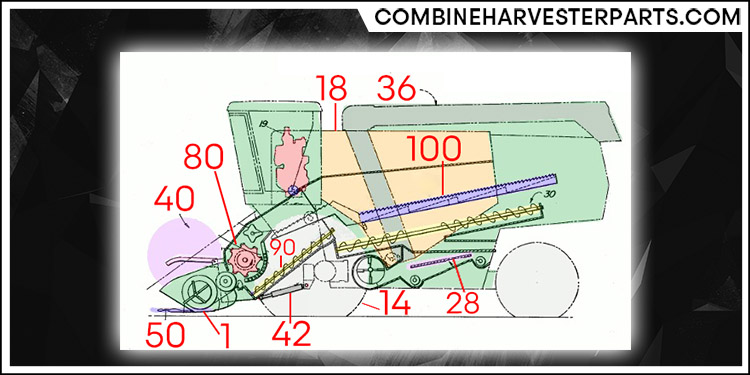

There are over 130 different combine harvester parts that make up a typical combine harvester. However, being a guide for beginners, I will focus only on certain key elements of combine harvesters’ structure.

A typical combine harvester comprises the following important parts:

- 1: Combine Header Auger

- 40: Combine Reel (indicated its position with a purple circle). It’s held in place by reel arms

- 50: Combine Cutter bar (blue, bottom)

- 80: Combine Threshing drum (red)

- 30/90: Conveyors and Combine Auger Screws (yellow) that move stuff through the machine

- 42: Hydraulic rams (gray, bottom) that lift the header up and down.

- 28: Combine Sieves (purple) that clean the grain.

- 100: Straw walkers (blue)

- 18: Combine Grain tank (orange). This sits like a saddle over the central, straw-walker mechanism, with a shallow middle part and two deeper sections that extend either side.

- 36: Unloading pipe (dark green), based on an auger mechanism.

- 19: Engine (red) sits behind the driver. The power shaft (blue, 102) drives all the machinery inside.

- 14: Front drive wheels (light gray) are fixed (do not steer). The rear wheels (15) swivel for steering the combine.

The Most Recent Updates On Market of Combine Harvesters [2021]

When I did research about the combine harvester, I found that information about the machine’s market is VERY scarce.

Thus, I decided to have a section focus ONLY on this data about:

- India combine harvester market

- Vietnam combine harvester market

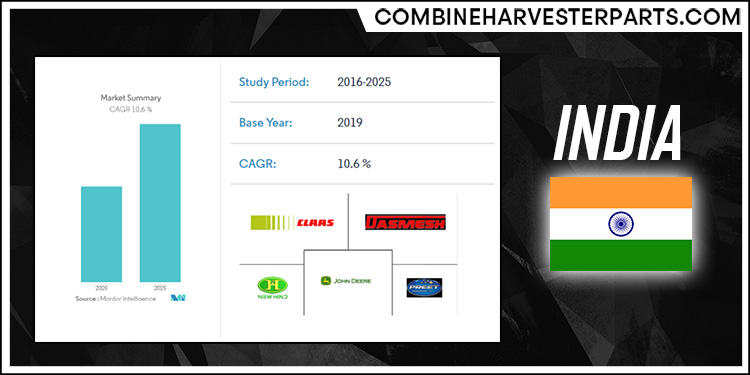

India – The World’s Largest Market Of Combine Harvesters

According to Mordor Intelligence, Indian market for combine harvesters has potential thanks to its expected growth rate of 10.6% during the forecast period 2020-2025.

Before, combine harvester is NOT an ideal choice, due to two reasons:

- The ample labor with low cost in India, which makes using machines a redundancy.

- The high risk of investing in such machines at the time, because of their high cost.

However, with rural work programs such as the Mahatma Gandhi National Rural Employment Guarantee Act (MGNREGA), the market of combine harvesters has experienced a quantum-leap development.

Nowadays, Indian market for combine harvesters is more energetic, with many BIG combine manufactures (Preet Group, Claas India, Dasmesh Group, John Deere India, etc.)

In India, self-propelled combines with high operating efficiency are VERY widespread. In 2019, it is estimated that over 60% of combine harvesters are self-propelled. It is expected to grow by 11.3% until 2025.

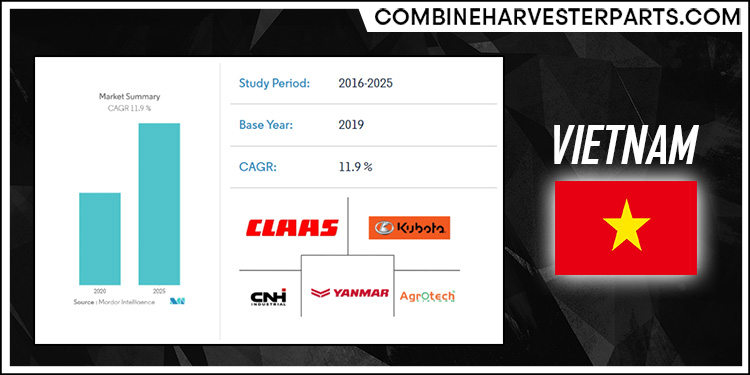

Vietnam – The Growing Market Of Combine Harvesters

Mordor Intelligence also reported that the Vietnam Combine Harvester Market was valued at USD 25.2 million (2019) and is expected to register a growth rate of 11.9% during the forecast period from 2020 to 2025.

During 2018, the total number of combine harvesters in Vietnam was 751 units, with:

- 90% are imported combine harvesters

- Only 10% being domestically manufactured.

In recent years, domestic combines have made many improvements. However, farmers still prefer imported units due to their HIGH quality and durability.

Top Four Combine Harvester Manufacturers In The World

This part will show you information about four top manufacturers of combine harvesters in the world:

- John Deere

- Massey Ferguson

- Case IH

- New Holland

Manufacturer #1: John Deere – PIONEER In Combine Harvester Industry

John Deere is the official brand name of Deere & Company – an American company, founded in 1837. The company operates mainly in agricultural, construction and forestry machinery.

According to the Fortune 500 America’s Ranking of 2020, John Deere was ranked 88th.

As of 2021, John Deere offered four different series combines, including:

- Eight models of S-series combine (S760, S770, S780, S790, S660, S670, S680 and S690). [26]

- Two models of X-series combine (X9 1000, X9 1100). [27]

- Four models of T series combine (T550, T560, T660, T670). [28]

- Four models of the STS series combine (also known as Single Tine Separation models).

Brand new equipment is available at every John Deere dealership in all states in the United States.

Manufacturer #2: Case International Harvester – SPECIALIST In Rotary Combines

Case International Harvester (Case IH) is a multinational company supplying agricultural equipment. Founded in 1985, the company now has business units in every state of the U.S.

Case IH offers six (06) models of Rotary combines. Their rotaries have various power capacity and grain output to fit diverse farm sizes (from family size to industrial level).

Rotary combines from Case IH are famous for their durability, as all models comprise the fewest moving parts of any combine in the industry. This trait helps simplify repairs to get farmers back into the field more quickly.

Manufacturer #3: New Holland – UNIQUE Twin Rotor Technology

New Holland is a popular brand of CNH Industrial, focusing on agricultural machinery production. The company was founded in 1895. In 2011, New Holland was considered the biggest manufacturer of combine harvesters in the world.

New Holland is famous for their exclusive twin rotor technology. It provides more centrifugal force and better threshing efficiency than standard designs.

Manufacturer #4: Massey Ferguson – FIRST Self-Propelled Combine Company

Massey Ferguson is another well-known American manufacturer of agricultural equipment. It was formed in 1953 via the merger of two farming machinery companies:

- Massey Harris (Canada), and

- Ferguson Company (Northern Ireland).

Massey Ferguson became the FIRST company to build self-propelled combines in 1938. Their combine harvesters provide the world’s FASTEST unloading rate, a 60% increase over the overall market. This characteristic helps get the job completed faster and more efficiently.

Conclusion

Congratulations to everyone who makes it to this point. I do not expect you to memorize everything. I just hope you understand the fundamental aspect of combine harvesters.

Besides this technical series into combine harvesters, I have many other articles reviewing famous combine manufacturers. Make sure to check them out, as they will surely offer you a more practical view.

Frequently Asked Questions On Combine Harvesters

During my writing of combine harvesters, I received many inquiries about this versatile machine. Thus, I decide to use this whole part to clarify all your questions relating to the topic.

Reference

- Highest Rate of Fatal Accidents Within Agriculture Industry. DAC Beachcroft. Retrieved May 28th, 2021.

- CLASS 6 SCIENCE – Separation of Substances. Soaring High. Retrieved May 28th, 2021.

- How To Sell: Leveling Systems Increase Harvest Productivity on Sidehills. Farm Equipment. Retrieved May 28th, 2021.

- Largest combine header in the world : MidWest Durus Premium 60′ – 18,3 meters. Youtube (Neotorious Gaming Channel). Retrieved May 29th, 2021.

- Combine Harvesting Animation (MCS). Youtube (Lonkhuyzen Channel). Retrieved May 29th, 2021.

- CLAAS TUCANO crop flow – straw walker animation / 2008. Youtube (CLAAS Channel). Retrieved May 29th, 2021.

- Maize Chopping Baling and Wrapping in one pass | New Holland FX60 & Agronic multibaler NI’J Holthoes. Youtube (Tractorspotter Channel). Retrieved May 29th, 2021.

- CR Opti-Spread™ Plus system. Youtube (New Holland Agriculture Channel). Retrieved May 29th, 2021.

- Combine harvesters. Explainthatstuff!. Retrieved May 29th, 2021.

- Driver’s view: John Deere CTS 9780i combine. Farmers Weekly. Retrieved May 29th, 2021.

- John Deere Combine Harvester S Series Overview. Machines4u. Retrieved May 30th, 2021.

- X Series Combines. John Deere. Retrieved May 30th, 2021.

- T-Series. Harvest in record time. John Deere. Retrieved May 30th, 2021.

- Case unveils new 8.5m combine header for controlled traffic farming. Farmers Weekly. Retrieved May 30th, 2021.

- Automatic retention of the combine harvester’s maximum capacity. Agromek. Retrieved May 30th, 2021.

- Massey Ferguson’s unrivalled harvesting heritage. Massey Ferguson. Retrieved May 30th, 2021.

- IDEAL combine harvester from Massey Ferguson receive Red Dot Award at ceremony in Germany. Agri Machinery News. Retrieved May 30th, 2021.