Combine header is one of the most important components of the combine harvesters, being attached at the front of the machine and performing the function of grain collecting.

Combine header comes in various shapes and sizes, and is fabricated specifically for harvesting certain crop plants.

Therefore, selecting the ideal combine header types is as crucial as choosing the combine harvester itself.

If you have an unsuitable choice, your crop gathering might become disastrous with low grain quality, less grain yield and thus your business may be unprofitable.

This is why it is critical to thoroughly understand the different types of combine headers.

We have taken time to research to be able to provide you with different types of combine headers in the following article.

Each combine header fits perfectly for certain types of grain. Let’s explore the most six common types of combine header.

Types of Combine Header

To perform the harvesting processes, certain special attachments of combine harvesters are required, including the front headers, cleaning sieves, stalk choppers and related material conveyors.

Among them, changeable attachments like front headers are indispensable for the cutting and collecting of crop plants.

Within the scope of this article, combine headers are divided into six (06) main types as follow:

| NO. | COMBINE HEADER TYPE | CROP PLANTS APPLIED |

| 1 | Grain header | Cereals with small grains |

| 2 | Draper header | Wheat, barley, oats, rye, triticale, rice, soybeans |

| 3 | Stripper header | Rice |

| 4 | Corn header | Ears only, or ears and stems |

| 5 | Sunflower header | Flower heads |

| 6 | Pick-up header | Beans |

Grain Headers

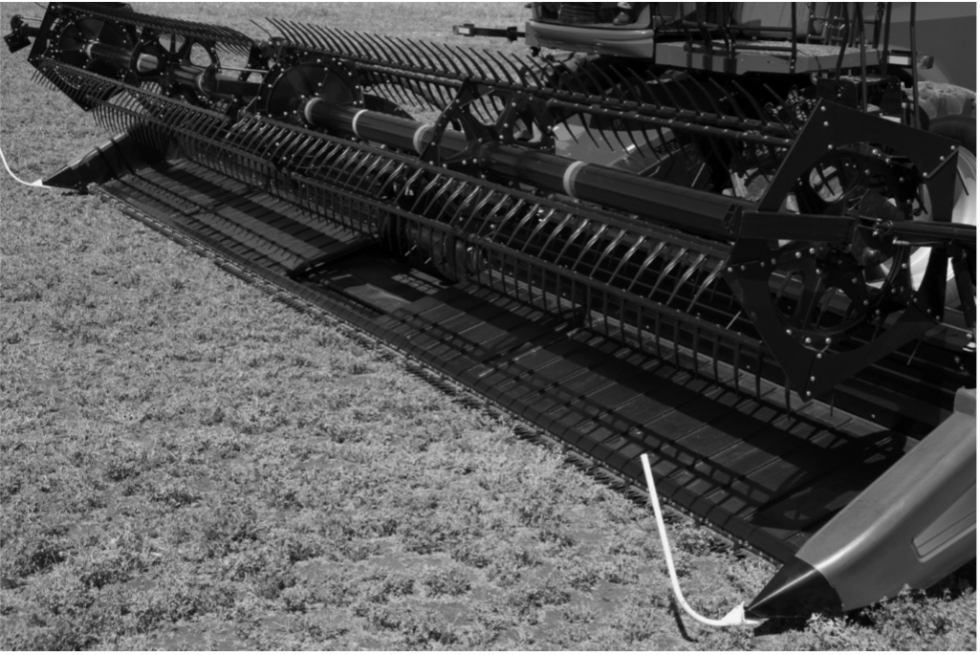

Grain headers are the most commonly used type of combine headers.

Grain headers are designed specifically for harvesting cereals with small grains, such as: wheat, oats, rye, triticale, oats, soybean, rice, milo, flax and other cereal crops.

The combine header in question is built in series of four to six different sizes, ranging from 6m to 12m (20-40 ft),

with the aim to match with combine harvesters of many sizes for a variety of crops as required.

The components of a grain header include:

a platform equipped with a frontal, reciprocating knife cutter bar;

two lateral dividers of the plants; cross-mounted crop-lifting devices;

a reel with slates and metal fingers (or plastic fingers);

and an intake auger facilitated with a retractable finger drum that delivers the collected crops into a combine-feeder house.

Some grain headers even have additional options, like: extendable platform, flexible floating cutter bar, side cutter bars, headlights, etc. However, all grain headers have a single-lever hydraulic hookup.

When the grain header operates, its reel rotates and thus, each slate with fingers comes into contact vertically with the crop plants.

The plants are then pushed towards the cutter bar, falling on the platform, and delivered to the center of the header via the intake auger.

During the harvesting processes, the grain can be shattered and thus increase the amount of grain losses.

These issues can be mitigated by adjusting an optimal cutting height of the plants, selecting a suitable position of the reel relative to the cutter bar,

as well as modifying the reel rotation relative to the combine harvester speed and crop type.

Draper Headers

Draper headers contain two fabric or rubber conveyors, together with a center feeding belt conveyor, instead of a cross auger like the case of grain headers.

Thanks to this combination, the materials are harvested and delivered towards the header center more quickly.

Therefore, it is fair to say that the draper headers allow higher efficiency and higher material throughputs.

Moreover, this type of header demands less power, and is provided with multiple options of cutting widths with flexible cutter bars.

However, compared to grain headers, draper headers require longer maintenance time.

One example of a draper header includes the MAXFLO header, designed by CLAAS.

This model features an intake unit consisting of two augers mounted laterally into the intake auger equipped with retractable fingers.

The auger speed comes with three different configurations of 150, 200, and 250 rpm, with reversible option for its moving direction (which can be set in the combine cab).

The speed of conveyor belts is also modifiable by the combine control system.

In some circumstances where crop swathing is demanded, draper header can be converted into a swathe platform by deselecting the center auger,

sliding one of the two belts closer to the feeding-house area, and having both belt conveyors move in the same direction, both left or right.

CLAAS is a German manufacturing company specializing in agricultural machines.

Currently, CLAAS is the European market leader in combine harvesters, with one of its most powerful model named CLAAS LEXION 8900.

Discover The best combine harvester in 2020

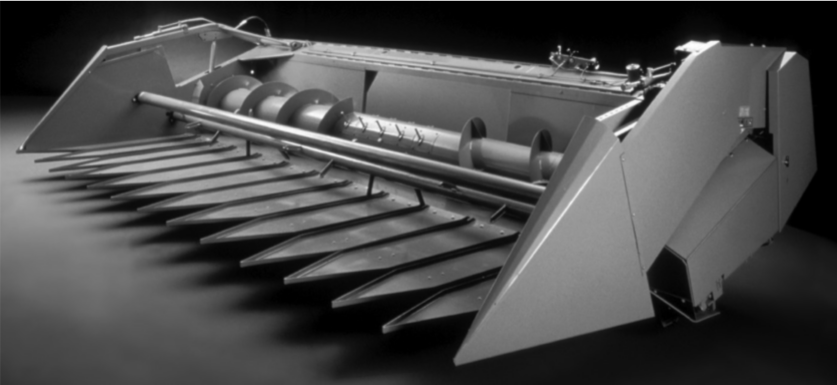

Corn Headers

Corn headers are designed for combine harvesters to collect 6-24 rows at a time.

These corn headers are created in a series of 6 rows, 8 rows, 12 rows, 16 rows, 24 rows and so forth.

The number of harvested rows is selected based on the capacity and engine power requirement of the combine harvesters.

Corn headers have three main types, depending on their main functions:

- Corn headers, used for gathering the ears only, while the stalks are cut down.

- Chopping corn headers, used for harvesting the ears and chopping the stalks. The stalk fragments are then spread on the farm.

- Integral corn headers, used for collecting the ears, chopping and collecting the stalk fragments. The fragments are to be left on the surface as a continuous swath, or to be stored in a trailer that moves in parallel with the combine harvester.

Sunflower Headers

Sunflower headers aim to cut the stalk beneath the flower head via a cutting bar.

During the harvesting processes, the hydraulic front plate has the role of keeping the flower heads in a forward position, while the snapping roller prevents the heads from being cut too soon.

To accommodate the most diverse conditions of crop plants during harvesting, and to maximize the material throughput, a suitable setting of seed pans, reel position, and rotation speed is needed.

The auger then collects all sunflower heads and delivers them into the feeder-house.

Instead of installing a reel, certain sunflower headers are equipped with poly snouts and guiding chains with fingers for each row.

However, such headers have higher sunflower seed losses on farms, due to the shaking incident during operation.

Pick-up Headers

Pick-up headers are also called the rake-up headers.

Such combine headers allow the swath harvesting of all crop types, especially beans, rapeseed, grass seed, peas, lentils and canola.

The pick-up header features a wide conveyor belt with equidistant bars carrying many metal tines (or fingers).

The role of metal tines is to go deep into the stubble to lift up the swath on the belt. After that, a large auger harvests the cereals, and pushes them into the feeder-house of the combine harvesters.

To be more versatile and flexible against the diverse harvesting conditions,

the belt and auger of pick-up headers are hydraulically driven to allow a variable speed and working capacity of the combine harvesters.

Under rough terrain conditions, the pick-up headers can float at a constant height from the soil in front of the machine, with the support of two or four individual rollers.

This type of header is equipped with a hydraulic multi-coupler which allows the headers to directly fit to the hydraulic system of the combine harvesters.

Stripper Headers

Stripper header is increasing its popularity in many regions, for its efficiency in harvesting small grains.

Over a quarter of rice in the United States, South America and Australia is collected with combine harvesters installing stripper headers.

Despite having a higher grain loss than other combine header types,

stripper header has many advantages, such as high throughput (up to 17 kg/s),

high collecting speed (as fast as 2.2 m/s or 5 m/h), reduced fuel consumption, and less demand for maintenance.

This type of combine header was originally designed by Keith Shelbourne (Shelbourne Reynolds, UK) in 1989.

The updated model of Shelbourne, the RVS and CVS stripper header, are in essence stripping rotors that spin under a modifiable hood and a small platform, followed by an intake auger.

As the combine harvester moves the header forward, the stripping rotors rotate backward and strip the grain from its ears or panicles.

Most grains are pushed directly from the rotor to the intake auger placed nearby.

And thus, only grain and some leaves pass through the threshing section of the combine harvesters.

The stems and MOG are left on the field.

Some modern stripper headers are facilitated with a variable-speed belt drive,

allowing easy adjustment of rotor speed for the operator in the combine cab.

Components of Grain Combine Headers

The ultimate goal of operating a combine harvester is to gather from the farm as much grain as possible.

And the first mechanical compartment that performs the harvesting of crop plants on farms is the combine header.

In this following section, Thanh Trung Combine Harvester Parts Manufacturer would like to focus more detailed on the components of Grain Combine Headers,

as they are one of the most popular combine headers being used nowadays.

As mentioned above, the grain header comprises eight (08) main compartments:

| NO. | COMPARTMENTS OF GRAIN HEADER |

| 1 | A platform |

| 2 | A frontal, reciprocating knife cutter bar |

| 3 | Two plants dividers which are placed laterally |

| 4 | Cross-mounted crop-lifting devices |

| 5 | An orienting reel with slates and plastic (or metal) tines/ fingers |

| 6 | An intake auger |

| 7 | Retractable finger drum |

| 8 | Power transmission |

All components of grain header are assembled on the frame of the combine header, which are welded to the structure.

In modern combine harvester models, the header section is kept at the suitable operating height, via the application of a closed-loop control system that gets the data from a sensor arm, which takes the form of a ground runner, engaging and riding over the soil surface.

Knife Cutter Bar

During the harvesting processes of grain headers, the crop plants are cut and chopped by the reciprocating cutter bar.

The cut of plant stalks are achieved between a rotating and a resting blade.

A standard reciprocating cutter bar (or sickle bar) is made up from three (03) items: the carrying frame, the cutting blade system, and the driving mechanism.

The cutting blade system: is equipped with a single, or double reciprocating multi-teeth (or multi-knife) bar.

With regard to single reciprocating multi-knife bar, it operates together with a stationary guard sickle which acquires the function of a carrying frame.

The multi-teeth knives and the end blade are assembled together on a flat bar, through the usage of the fasteners.

Regarding the cutting blade, it is a tempered-steel plate in the shape of a trapezoid.

Besides the blade, there are guard fingers whose role is to divide the plants and guard the knives against rocks or soil unevenness.

Hence, a clearance between the cutting knives and guard fingers (or counter-knives) is highly recommended.

The plant harvesting processes of the reciprocating cutter bar can be broken down into three (03) main following periods:

| NO. | PERIODS | REMARKS |

| 1 | Plant stems separation and the slippage along the fingers toward the cutting knives. | The fingers divide the plants in strips, by inclining them laterally, while the cutting bar moves forward. |

| 2 | Lateral inclination of the plants between the cutting knives. | In this period, the stems continuously and strongly come into contact with the cutting edges of both the knives and counter-knives. |

| 3 | Stem cutting and release of the cutting knives from the harvested material. | The stems are cut and chopped through a shearing mode. Different geometric designs of the cutting knives provide specific required cutting forces and cutting areas covered by the knives motion. |

The cutting quality of the reciprocating cutter bar relies significantly on:

- The sharpening angles of the blade and counter-knife, with the optimum angle settings ranging from 19°–25°.

- The cutting edge thickness, with recommended values fall between 25-30 μm (0.0001–0.0012 inch).

- Clearance between the blade and the counter-knife mounted on the finger, with maximum figures should be 0.3 mm (0.012 inch).

- Cutting speed, depends on the crop types and is set in the combine cab by the machine operator.

Beside grain headers with the application of reciprocating knife cutter bars, other combine header types have their own unique cutting tools.

For instance, corn header and sunflower header are equipped with the rotary blade cutters, or cutting discs.

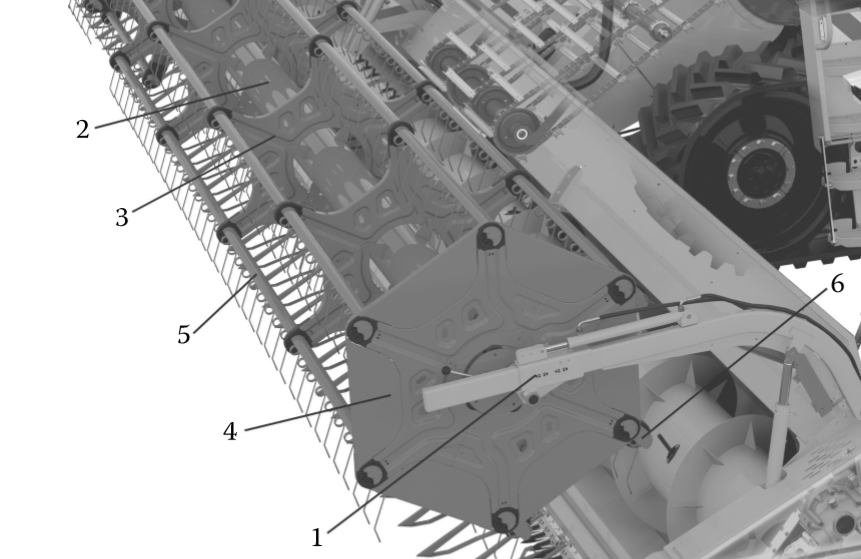

Orienting Reel

Being the first compartment of a combine header to directly touch the crop plants on farms, the reel is one of the most important items that a combine harvester possesses.

The orienting reel, spanning the full length of a combine header, has a pentagonal or even hexagonal-prismatic shape. Main construction of an orienting reel includes:

- (1) Reel arms, which can change position via hydraulic adjustment.

- (2) & (3) A central tube, which has equidistant flanges.

- (4) An eccentric end shield.

- (5) Bars with fingers (or tines).

- (6) End cracks.

And power transmission.

The orienting reel’s main functions are to divide the plants on farms into bunches, and to orient (or guide) them toward the header cutter bar.

The reel also assists the plant cutting process, and helps shunt all of them onto the header platform.

In certain circumstances, the reel is also required to lift up the plants falling on the soil surface,

and to minimize grain shattering caused by the impact of tine bars on the plant ears.

As the combine harvesters are driven forward on the field, the tine bar is required to enter through the crops in a vertical manner.

The stalks are then bent backward toward the cutter bar, which chops them at a desired height of just below the grains heads.

Header Augers (Intake Augers)

The header augers, or sometimes called intake augers, have the role of gathering the cut material and delivering it to a component named retractable-finger drum,

and eventually placing the material through the feeder-house of the combine harvesters.

Despite the design and correct setting of the intake auger is often overlooked, such features have a significant impact on the combine harvester capacity and efficiency.

The intake auger spans the full width of the combine header to have the ability of dragging the cut plants inside.

Located symmetrically with the retractable-finger drum are two similar sections of the cross auger, each of which is composed of a steel barrel and a helical high spiral.

Regarding the spirals, with opposite wrapping angles, the spirals can help collect and transport the crops from the lateral sides to the header center.

The retractable-finger drum performs the action of pushing collected material through to the bottom section of the feeder-house.

The drum’s main components include a crankshaft (with a fixed but adjustable position) and the fingers (which slide through spherical bushings mounted on the auger barrel on a helical path).

Between the two close fingers lies a distance of approximately 25-30 mm. The drum’s length falls around 1 to 1.5m (40 to 59 inches).

Conclusion

We have gone through everything about one of the main compartments of the combine harvesters – combine headers,

from their classification of six widely-used types (Grain header, Draper header, Corn header, Sunflower header, Pick-up header, Stripper header) to their detailed composition (Knife cutter bar, Orienting reel, Header auger).

You can find more general information about combine harvesters through our articles.

Each combine header type is built for the goal of handling certain crop plants.

As there are a wide range of different crop plants out there, combine harvesters also demand diverse header types to accommodate their different harvesting conditions.

It is fairly to say that the right choice of combine header can significantly enhance your work efficiency and performance, via higher material throughput and less grain damage.

Therefore, successful crop gathering begins with the right choice of combine header, as it determines the grain amount and quality being input into the machine.

After all, you can only handle the material you put into the combine harvesters.

By installing a suitable combine header, you can unlock the full operating potential of your combine harvesters.

No matter the working environment, on wide open prairies or highly inclined terrain,

if harvesting grains is your main mission, a combine header shall assist you on achieving such task: everywhere, with all crops plants and in all fields.

Do you wonder what happens next after the plants are collected and pushed inside the combine harvesters? Our next stop will be the threshing unit of the combine harvesters.

Link out and prosper!

https://books.google.com.vn/books/about/Combine_Harvesters.html?id=yn5jCgAAQBAJ