TIG Welding Titanium is difficult, or is it a simple process?

This article will provide you with the answer, by covering:

- Shielding Gas for TIG Welding Titanium.

- Best Tungsten for TIG Welding Titanium.

- Top options for TIG Welding Titanium Filler Rod.

- Pre-welding Preparation – The #1 thing to do before TIG Welding Titanium.

- TIG Welding Titanium Tips and Tricks.

- Assess your Titanium TIG Welds via Colors.

Everything is set! Let’s go now!

Shielding Gas for TIG Welding Titanium

1. Shielding Gas Type for TIG Welding Titanium

Pure Argon (or Pure Helium) is the optimal selection for shielding gas of TIG Welding Titanium.

A combination of Argon and Helium (75% – 25%) is also acceptable, as long as it provides an inert environment for Titanium.

When we say Pure Argon (or Helium), we actually mean “extremely pure”, with at least 99.999 percent of purity.

So, for TIG Welding Titanium, a good suggestion is to get your Argon shielding gas from trusted suppliers only.

Titanium is extremely reactive with air, dirt, oil and other chemicals in the atmosphere to form brittle products.

Thus, it is a MUST to TIG weld titanium in a complete inert environment of Pure Argon (or Pure Helium).

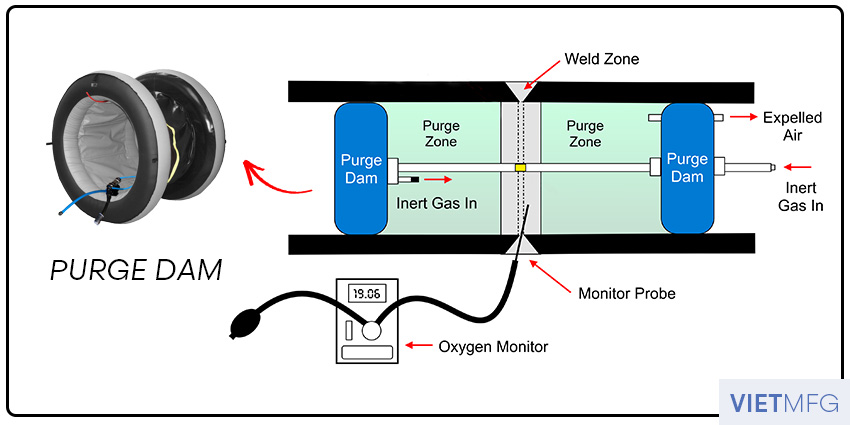

By that we mean, not only the front of your workpiece, but the back must also be protected from the atmosphere.

- This purging process is very essential for TIG Welding Titanium Tubing.

- When back-purging, you will need purge dams (water-soluble dams, inflatable bladders, etc.)

- Your shielding gas, Argon, will flow into these “dam areas” and replace existing oxygen there.

- This helps ensure the purest welding environment for TIG Titanium.

It is a common practice to perform TIG Welding of Titanium in a vacuum-assisted chamber.

- This welding chamber offers glove ports and a hemispherical, plexiglas dome for observation.

- After placing the workpiece inside, air is quickly removed via a vacuum pump, leaving the internal environment with inert gas only.

- Thus, a vacuum-assisted welding chamber provides a purer and more controllable environment for Titanium TIG Welding.

Yellow-straw discoloration can happen to your titanium workpiece, even if your shielding gas is just a little bit less pure than required.

To know if your Argon (or Helium) is pure enough, here is a tip for you:

- Run gas flow for a few seconds before switching to high-frequency start.

- During these first few seconds, if you see some blue tinting and mottling, your Argon is not pure enough. So, stop and re-check your shielding gas.

- If you see a uniform color, then your shielding gas is pure and evenly dispersed over the workpiece. Then, you can switch to high-frequency start.

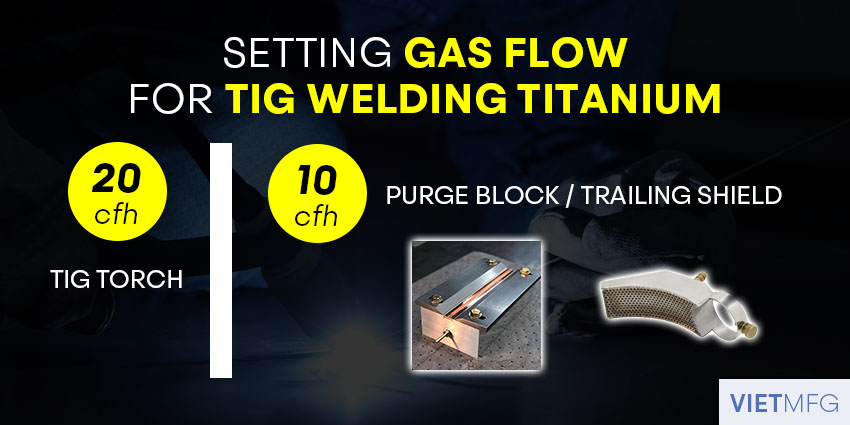

2. Setting Gas Flow for TIG Welding Titanium

The optimal gas flow setting for TIG Welding Titanium is 20 cfh for the TIG Torch.

If you install a trailing shield or purge block, set the gas flow at 10 cfh.

- Trailing shield: offers greater Argon protection to your titanium workpiece from oxygen and cracking defects. It conforms to the shape of your workpiece (especially your tubes) and follows the TIG torch around such tubes.

- Purge block: helps supply the shielding gas coverage on the back and bottom sides of a weld joint. It is usually made of porous copper sheet or stainless steel wool. Purge block allows shielding gas to be evenly distributed and smoothened out over the workpiece.

3. Maintaining shielding gas protection for your Titanium during high temperature

Remember that the heat-affected zone (HAZ) of your titanium workpiece must be protected from the atmospheric contaminants until the temperature drops under 800 degrees Fahrenheit.

The reason is that titanium is very reactive with airbornes such as nitrogen, hydrogen, oxygen, etc. in the atmosphere.

It is highly recommended to use an infrared temperature gauge to make sure your titanium workpiece cools down to below 800 degrees Fahrenheit before you cut off your gas flow.

Best Tungsten for TIG Welding Titanium

For TIG Welding Titanium, 2% Ceriated Tungsten Electrode (EWCe-2; Orange Tungsten) is your top choice.

The optimal tungsten size depends on your welding amperage, which is specified in the following table:

| Amperage Range | Tungsten Size Range |

| < 125 amperes | 1/16 inch or smaller |

| 125 – 200 amperes | 1/16 inch – 3/32 inch |

| > 200 amperes | 3/32 inch or 1/8 inch |

Regarding the electrode stick-out, you should maintain the stick-out around 1.5 times of the tungsten diameter.

Too much stick-out will block your view and make it harder to perform a good TIG Welding session.

Top Options for TIG Welding Titanium Filler Rod

When choosing Filler Rod for your Titanium TIG Welding, the #1 rule is to select a suitable filler rod to match your titanium grade.

In fact, it is not easy to do, as there are many many different grades of titanium.

According to ASTM International (American Society for Testing and Materials), there are 31 grades of titanium with different formability, corrosion resistance and weldability.

Once you have chosen your appropriate filler rod by applying that #1 rule, the handling of that filler rod is also very important.

By “handling”, we mean 2 tasks: cleaning and storing.

Firstly, cleaning your filler rod should be on top of your to-do-list.

- Use acetone or MEK (methyl ethyl ketone) to clean your rod; and remember to put these combustible chemicals away before you start your TIG Welding Titanium session.

- Moreover, wear nitrile gloves when you touch your titanium rod, to prevent natural oils from your hands contaminating the rod (or even the workpiece).

- Also, clip off the end of your filler rod before welding to further prevent contamination.

Secondly, storing the filler rod is also the next essential thing to watch out for.

Remember to store the filler rod in airtight jars to make it safe for future reuse.

Below is the table that recommends certain filler rod grade to your workpiece:

Table 01 – Recommended Table of Filler Rod Grade for your Titanium Workpiece

| Filler Rod Grade | Titanium Grade of Workpiece | ||||

| ERTi-2 | ERTi-3 | ERTi-5 | ERTi-9 & ERTi-9ELI | ERTi-23 | |

| Grade 1 (CP-1) | X | ||||

| Grade 2 (CP-2) | X | ||||

| Grade 3 (CP-3) | |||||

| Grade 5 (Ti6A14V) | X | ||||

| Grade 9 (Ti3A12.5V) | X | X | |||

| Grade 23 (Ti6A14V ELI) | X |

* CP : Commercially Pure.

* ELI : Extra Low Interstitial.

Welder Setup for TIG Welding Titanium

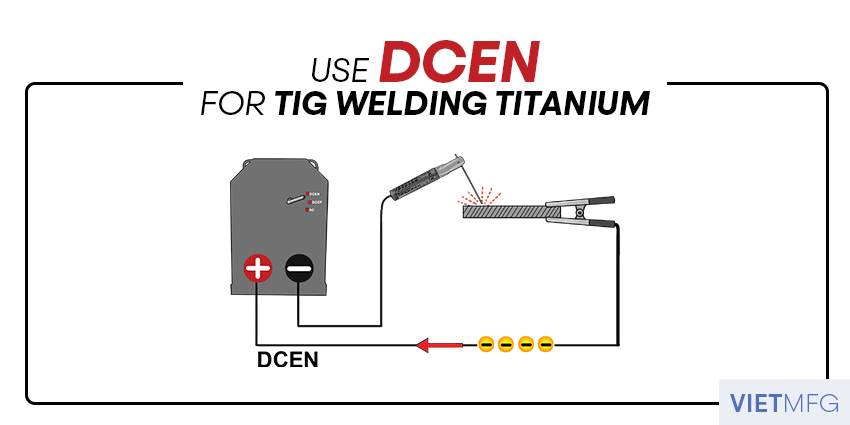

1. Polarity Setting for TIG Welding Titanium

For TIG Welding Titanium, set your polarity to DCEN (straight polarity).

DCEN gives you a deeper penetration profile and a narrower weld bead than DCEP. So, it is a good choice for TIG Welding Titanium.

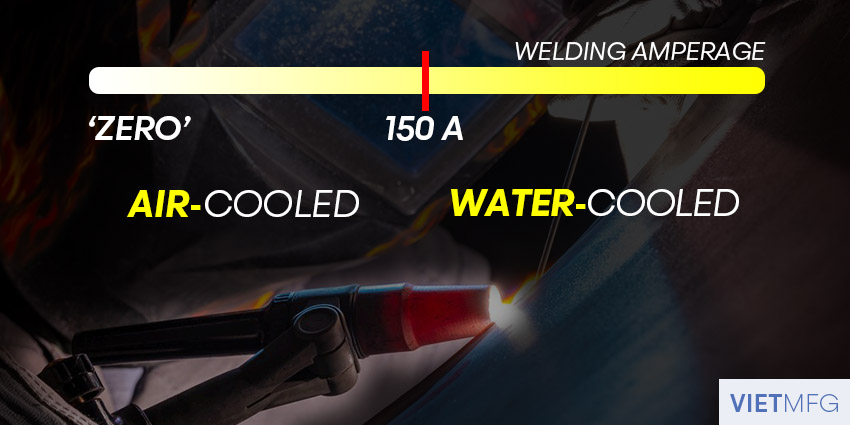

2. TIG Torch Type for TIG Welding Titanium

Similar to TIG Welding of other materials, TIG Welding of Titanium can utilize both air-cooled and water-cooled torches.

While air-cooled type is more affordable, water-cooled torch can operate with high-temperature for longer periods of time.

Water-cooled TIG Torch is also more compact and easily steerable.

To decide between air-cooled and water-cooled type, let’s base on your welding current:

- If you are TIG welding below 150 amperes, go with air-cooled torches.

- If you are planning to weld at high amperes for extended periods, water-cooled types can help you.

3. Amperage Settings for TIG Welding Titanium

Set your amperage current to at least 250 amperes, which will work perfectly with TIG Welding Titanium.

Remember, test your gas flow for a few seconds before switching to high frequency arc mode.

Pre-welding Preparation – #1 Thing to do before TIG Welding Titanium

What sets TIG Welding Titanium apart from TIG Welding other materials is that titanium requires extreme cleaning before being welded.

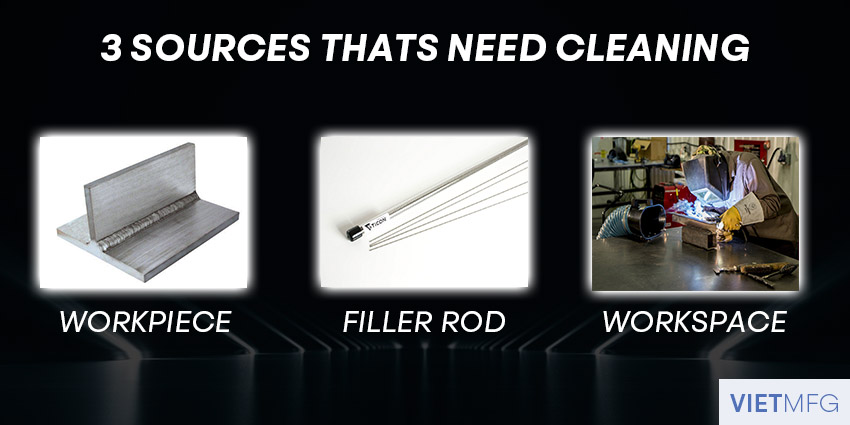

Three sources that need cleaning are: the titanium surface, the filler rod, and your workspace.

Firstly, it is the cleaning of your titanium surface.

- Similar to aluminum, titanium can form oxide layers easily, even at room temperature.

- These layers have higher melting temperature than the titanium itself, and thus must be removed prior to your TIG welding session.

- To remove these oxide layers, either use a grinder or carbide file that is dedicated only for titanium.

- One small note when using a grinder, grind at low speed to prevent excessive heat.

- Make sure to collect and remove all titanium dust from grinding operations, as it can be explosive if accumulated (titanium dust is used in making fireworks, so be careful with it).

- Do NOT use steel wool or abrasive as they can contaminate the surface.

Secondly, for cleaning filler rods:

- Wipe them with acetone (or other cleaning chemicals) and store them in airtight jars.

- Always wear nitrile (or plastic) gloves to handle the rods (as well as the workpiece).

- Stay away from rubber gloves as they contain chlorine, which will not react well with titanium if coming into direct contact.

Thirdly, to clean your workplace:

- Use a dilute solution of sodium hydroxide to sweep away all contaminants.

- Also, use a hot-air blower (hair dryer style) to ensure no moisture staying around your workplace, and even being condensed in your workpiece.

- Before turning on the hot-air blower, remember to clean all your flammable chemical solvent.

Some Tips and Tricks for TIG Welding Titanium

1. Ensure perfect fit-up conditions

Fit-up condition of your weld is critical in TIG Welding of tubing.

And since most TIG Welding Titanium involves tubing, fit-up condition is surely an important factor to watch out for.

Good fit-up prevents oxygen from entering and contaminating the weld.

For TIG Welding Titanium, fit-up should be perfectly square to reduce the heat and filler metal required to fill the joint.

When the fit-up is perfectly set up, clamp your workpiece onto a workstation to make sure it is tightly and accurately positioned.

For certain thin titanium pieces or tubing, consult with your welding equipment supplier for advice on preheat, and even postheat.

2. Certain remarks during your Titanium TIG Welding sessions

This tip will mention some key remarks during 3 stages of your TIG Welding Titanium: before, during, and after welding.

Firstly, before welding:

- Cut off the end of your filler rod to prevent contamination.

- Run gas flow for a few seconds before actually striking an arc (watch out for blue tinting).

Secondly, during welding:

- Switch to high-frequency arc-starting feature to start welding.

- Maintain torch angles, travel speed and filler wire angles similar to when you TIG weld stainless steel.

- Keep the filler rod inside the shielding gas coverage during the TIG welding session.

- Control your heat, as excessive heat can cause cracking.

- Use dab technique at a steady travel speed with your filler rod.

Thirdly, after welding:

- Maintain shielding gas postflow for about 20 to 25 seconds, until the temperature of the titanium workpiece goes below 800 degrees Fahrenheit.

- Inspect your final welds either by bare eyes (look at the color) or through certain testings (dye penetrant inspection, ultrasonic, X-ray, hardness testing, etc.)

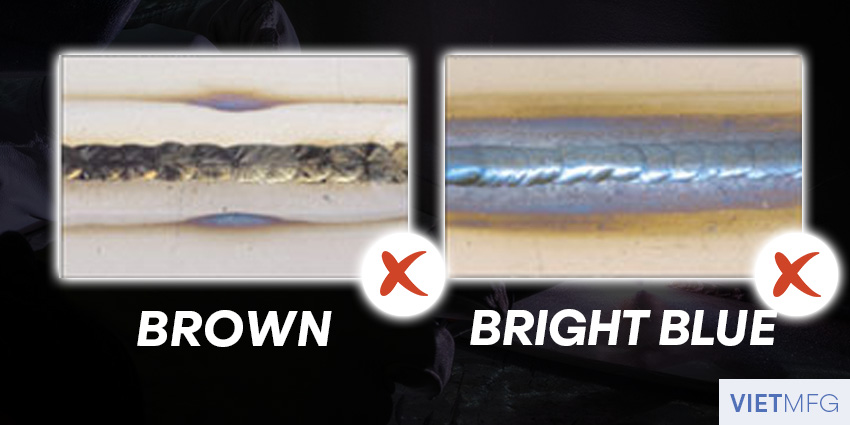

3. Assess your welds through colors

Discoloration of Titanium after TIG Welding can be caused by the following reasons:

- Using a filler rod that is not made of titanium (stainless rod or nickel alloy rod, etc.)

- Not provide shielding gas coverage for the backside of your workpiece.

- Not using a large enough cup/ nozzle (over 7/16 inch), or not equipping a trailing shield to your torch.

Ideally, the perfect color for TIG Welding Titanium is silver.

However, some welding codes and standards accept straw, or even a little bit of blue to be successful Titanium TIG Welding.

The rest of this article will include a table of acceptable and unacceptable colors of TIG Welding Titanium, as well as illustrating pictures.

Table 2 – Compilation of TIG Welding Titanium colors.

| Weld Color | Acceptable/ Unacceptable |

| Bright Silver | Acceptable |

| Silver | Acceptable |

| Light Straw | Acceptable |

| Dark Straw | Acceptable |

| Bronze | Acceptable |

| Brown | Acceptable |

| Violet | Unacceptable |

| Dark Blue | Unacceptable |

| Light Blue | Unacceptable |

| Green | Unacceptable |

| Gray | Unacceptable |

| White | Unacceptable |

Conclusion

That’s it! Do you have the answer for the opening question?

TIG Welding Titanium is not difficult at all, since you have read the above content.

As long as you ensure the titanium workpiece is clean before the welding process, with appropriate setups, you shouldn’t have any difficulty at all with TIG Welding Titanium.

Reference

- Welding Principles and Practices (5th Edition) – McGraw Hill Education. Edward R.Bohnart. [2017]

- How to Set Up a TIG Welder for Mild Steel? Welding Mastermind. Retrieved September 24th 2020.

- Welding Mild Steel Sheet Metal | TIG Time. Youtube (Weld.com channel). Retrieved September 24th 2020.

- TIG Welding Mild Steel. Youtube (WeldFever channel). Retrieved September 24th 2020.

- TIG for titanium tubing. The Fabricator. Retrieved October 18th 2020.