TIG Torch is one must-have equipment to perform TIG Welding.

This article is to give fabricators basic knowledge about TIG Torch by covering:

- What a TIG Torch is and its application

- Fundamental parts of a TIG Torch.

- Explore different types of TIG Torch.

- Must-have checklist before choosing your own TIG Torch.

- 04 best models of TIG Torch in 2020.

Let’s explore the equipment “TIG-ether”!

What is a TIG Torch?

TIG Torch is the equipment directing the tungsten electrode into the arc, conducting power to the electrode, and providing shielding to the arc area.

For example, if you are planning to TIG Weld Stainless Steel, or any materials, TIG Torch is an item that cannot be missed out!

There are many different types of TIG torches.

Each torch model is built specifically for a separate welding task.

Normally, fabricators prefer light and compact torches which fit in their hands for flexible operation.

However, the world of TIG torch is very large, ranging from compact designs to torches used in heavy welding.

However, usually, a welder will equip themselves with two torches: one for common tasks, and the other for specialty tasks.

Some famous manufacturers of TIG torch include: CK Worldwide, Miller Electric, Lincoln Electric, Weldcrafts, etc.

What is a TIG Torch used for?

A TIG torch performs four following functions:

- Holding the tungsten electrode: TIG torches allow you to use tungsten electrodes of varying diameters. The torches are equipped with a collet (a piece that holds the electrode). Collets of different sizes are used for electrodes of different diameters.

- Providing an electrical connection to the tungsten electrode: TIG torches control the electricity current with a foot pedal or a switch attached to the torch.

- Directing shielding gas flow to protect the welding area: Shielding gas (inert gas) is fed through a nozzle to the welding area. The gas comes out of a ceramic cup that’s fitted to the torch. Similar to collets, ceramic cups also come with different sizes to produce a suitable flow rate of shielding gas.

- Protecting fabricators from electrical accidents: TIG welding results in massive amounts of electricity. TIG torch helps insulate the dangerous electrical connections to provide safety for fabricators.

TIG torch is a critical part of any TIG welding setup.

What are the Fundamental TIG Torch parts and components ?

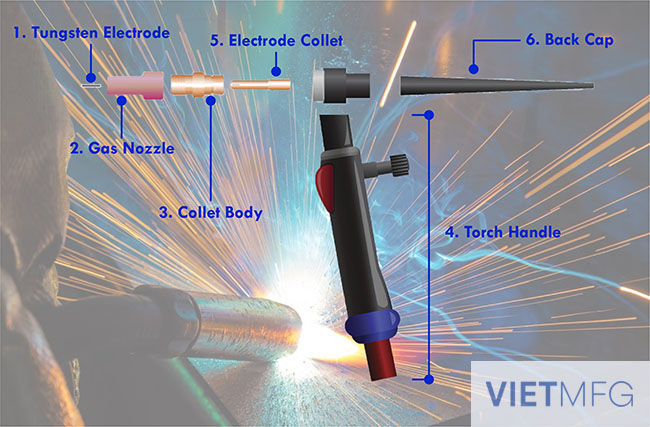

TIG Torch parts include six following basic items:

- Tungsten electrode

- Gas nozzle

- Collet body

- Torch handle

- Electrode collet

- Back cap.

Tungsten electrode

Tungsten electrode is a secret weapon used in TIG Welding.

There is a lot to discuss about this item, which is the main topic of another article.

Make sure to check it out, to fully understand its power.

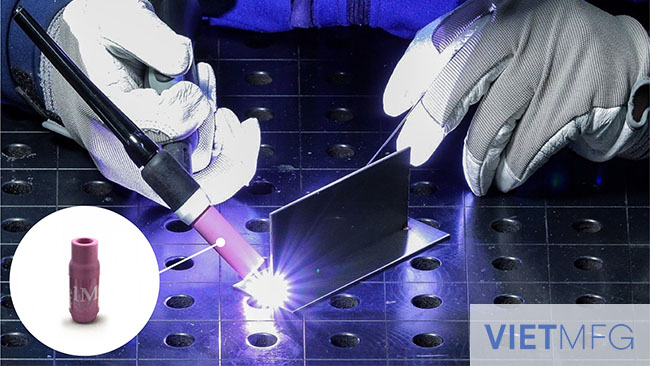

Gas nozzle

Gas nozzle (or gas cup) is mounted at the head of the torch, used to feed shielding gas to the welding area.

The material of the nozzle must be highly heat-resistant, such as ceramic composition, glass, metal, etc. thanks to their unique advantages. Specifically:

- Ceramic nozzles: provides welding currents up to 250 amperes.

- Metal nozzles: are capable of high welding currents (over 250 amperes).

- Glass nozzles: allow fabricators to watch the weld puddle without any blind spots.

Gas nozzles also come with varying sizes, indicated by numbers such as 4, 5, 6, 7 and 8. These numbers mean the nozzle size in the sixteenths of an inch. For example, a nozzle size 5 indicates 5/16 inch diameter.

A simple rule is to choose a nozzle with a diameter that is from 6 to 8 times the electrode’s diameter. Selecting a gas nozzle with wrong size can seriously affect your welding work:

- Nozzles with too small diameter tend to overheat and break.

- Nozzles with too big diameter provide poor gas shielding, and waste gas also.

Collet body

A collet body (located inside the white dot area) helps complete the electrical connection.

It is installed into the TIG torch and has holes to release the shielding gas.

A proper collet body must fit with the tungsten electrode and its respective collet.

The size of collet bodies ranges from 0.020 to 0.25 inches.

They are made of standard grade copper or tellurium copper (an alloy of copper and tellurium).

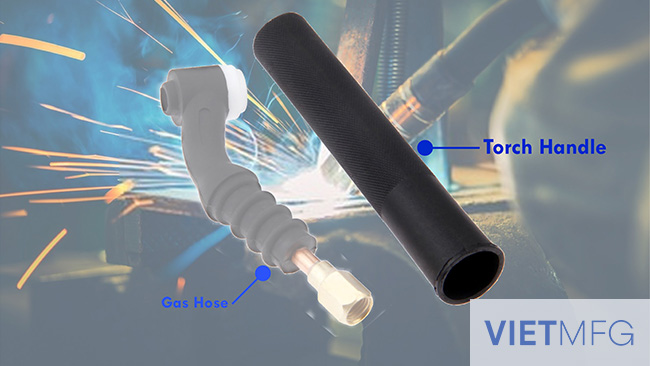

Torch handle

By insulating electrical connections, torch handle (or torch body) is the safe place for fabricators to hold and perform welding activity.

Torch handle covers the gas hoses located inside.

Removing the handle will reveal which torch you are having.

Details about this classification will be discussed later in this article.

Electrode Collet

Electrode collet is an item used for holding the tungsten electrode in position.

It is installed at the back of the torch and slides into the collet body.

It comes in different sizes to fit the electrode size.

Just like collet bodies, collets are also made of standard grade copper or copper alloys.

Back cap

Back cap is also installed at the back of the torch, to house the extra length of the tungsten electrode.

It features an O-ring to lock the shielding gas inside the torch and ensure the gas moves to the front.

Back cap is important in keeping the tungsten electrode in place.

It applies pressure to the collet and forces the collet against its collet body.

There are three main types of back cap to fit different electrode sizes:

- A short (or button) back cap: allows for welding in restricted areas, but requires short tungsten electrodes (less than 2 inches) which are very rare and costly.

- A medium back cap: fits with longer tungsten electrodes (up to 3 inches).

- A long back cap: is most preferred by fabricators, as it can go with very long tungsten electrodes (up to 7 inches).

Explore 2 different TIG Torch types

Air-cooled VS Water-cooled

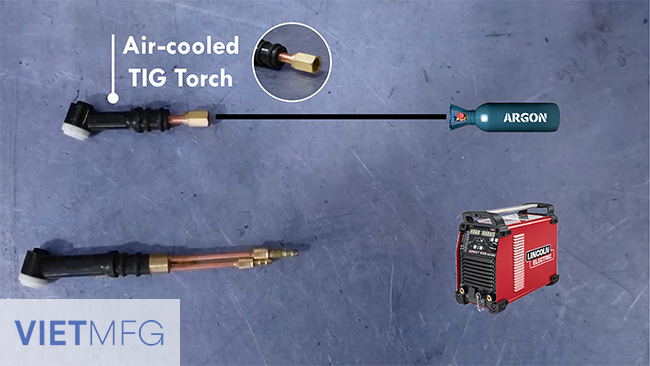

To keep things simple, there are only 2 types of TIG torches: Air-cooled (or gas-cooled) torch and Water-cooled (or Coolant-cooled) torch.

What is Air-cooled Torch (Gas-cooled Torch)?

Air-cooled torch, or gas-cooled torch, uses air (or gas) to cool itself down between welding sections.

In other words, they require some cool-down time during operation.

Thus, if you are not concerned about your torch getting overheated, or if you do not have a cooler nearby, air-cooled torch is an ideal choice.

It is easy to set up, but is limited to 200 amperes only.

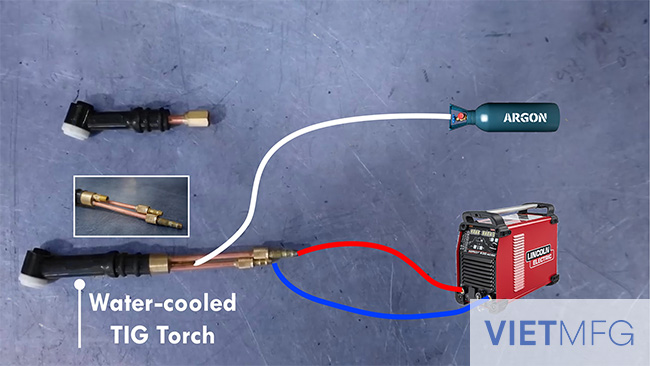

What is Water-cooled Torch (Coolant-cooled Torch)?

Water-cooled torch uses water (obviously) to refresh the torch instantly when it gets too hot. Thus, you can reduce your cool-down time, like in the case of air-cooled torches.

Water-cooled torch is also capable of higher welding currents (up to 500 amperes).

However, setting up a water-cooled torch is much more complex.

How to know which is air-cooled, which is water-cooled?

The answer is very simple.

Just remove the torch handle, and count the gas hoses inside:

- If it has only ONE single line going in, it is air-cooled.

- If it has THREE lines going in, it is water-cooled.

Which torch type should you use?

If you are having that question in mind, then ask yourselves this: Do you have a water cooler?

- If the answer is YES, go with water-cooled torch.

- If the answer is NO, stick with air-cooled torch.

TIG Torch family

The torch family is generally identified by a universal number system.

Normally, there are six torch families, indicated by the following six numbers:

- #24, #9, #17, #26 (air-cooled).

- #20 and #18 (water-cooled).

| NO | TORCH FAMILY | TORCH TYPE | POWER RATING | FEATURES |

| 1 | Torch #24 | Air-cooled | 80 amperes | LESS commonCompact designFits in tight spaces |

| 2 | Torch #9 | 125 amperes | CommonFits in tight spaces | |

| 3 | Torch #17 | 150 amperes | VERY commonBigger in sizeHandles various fab work and welding | |

| 4 | Torch #26 | 200 amperes | Very large in sizeHandles heavy welding | |

| 5 | Torch #20 | Water-cooled | 250 amperes | Same size as #9, but double in power rating |

| 6 | Torch #18 | 350 amperes | A combination of #17 and #26Handles very heavy welding |

Can we switch one torch family for another torch family?

To switch one torch family for another, they need to have similar thread. If they do not, you have to change the entire line with it.

Thus, out of all of those torch families, the only pairs that you can switch freely are Torch #17 and Torch #9.

Everything else has to have a separate line or a line that matches its thread.

Extra variants (options)

Apart from types and families, TIG torch has additional options called “variants”.

Here are four most common variants you can find:

Rigid (RG)

The first option is Rigid.

Rigid means the torch is stationary and does not do anything.

It does not flex, or move.

Also, It does not have a valve, or any attachment on it.

It has only a single line in (or three lines in if you have a water-cooled setup).

Rigid is the basic option that is available in every torch family.

Flex Head (FX)

The next variant is Flex Head.

The Flex Head is exactly what it does in its name: It flexes and moves.

The benefits of the Flex Head are being able to move the torch into difficult positions like an inside corner, or an edge weld.

Another benefit is just being able to see what you are doing from your point of view with nothing in the way.

Valve (V)

Another variant is the Valve.

The Valve is for turning the gas on and off manually, and is attached on the torch handle.

We have 02 types of torches with valve: Rigid Valve and Flex Valve.

If you have a machine that does not have an internal solenoid valve for your gas control, then a torch with Valve is the right “magic wand” for you.

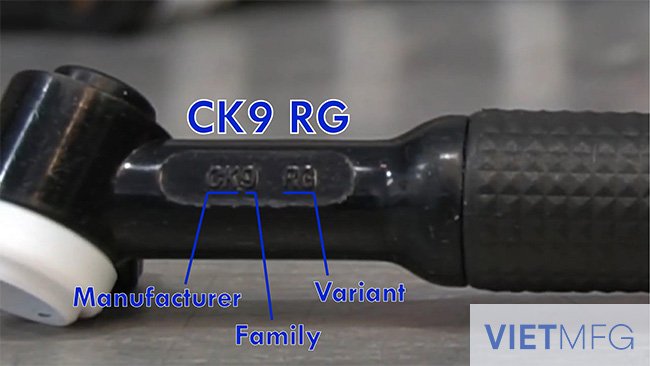

How to identify the variant of your TIG torch?

All information about your TIG torch, including variants, are shown at the neck of the torch.

Let’s learn how to read these information by examining the following examples:

Our torch here shows “CK9 RG”:

- CK: This prefix before the number usually indicates the manufacturer name (or whatever they use to identify that this is their torches). “CK” here means the company name CK WORLDWIDE.

- 9: This number is the family identifier. So, this torch belongs to #9 family.

- RG: This stands for Rigid – our variant indicator. Other options are displayed in a similar way, like V for Valve, or FX/ F for Flex Head.

- So in short, “CK9 RG” means that this torch is manufactured by CK WORLDWIDE, belongs to #9 family and its variant is Rigid (just a simple and straight-up torch).

Please keep in mind, there is no universal rule for showing these information.

This means, not all torches are going to have RG next to them as an indicator that it is Rigid (or FX, V).

And of course, not all of them are going to have any kind of manufacturer prefix.

Sometimes, you will just see number 9, or see absolutely nothing at all on some cheap torches.

If it does not say F, do not try to F it!

If you do NOT see the letter that indicates your options, be very careful with your torch.

The tricky part is to identify between Rigid and Flexible (Flex Head).

In these cases, do not try to F your torch, or bend its neck!

Otherwise, it would go from F to B, which means Broken.

So, remember this line: If it does not say F, do not try to F it!

(6) MUST-CHECKED features before choosing a TIG Torch

1) Cooling Method

The first and most important thing to check is the torch’s cooling method, whether it is air-cooled or water-cooled.

Air-cooled types:

- Are more popular in the market, thanks to their simple setup and low investment cost. It is suitable for outdoor projects where there is no water access.

- However, it cannot weld at high electrical current over 200 amperes. It also requires many pauses during operation to cool down.

Water-cooled types:

- Are suitable for indoor and hot welding stores. It allows fabricators to use the torch at high amperes for a longer time period.

- However, water-cooled torch is more expensive, with a more complicated setup process. Leaks and water pump failures are high possibilities.

2) Power Rating

Another important factor to look out for is the amperage rating of your torch.

To identify the amperage requirement, you need to know well about your welding project.

- If you are welding for hobby with simple equipment at home garage, you could consider the maximum 200 amperes.

- However, if your project is more complicated and takes place in a machine shop, you will need at least 250 amperes for more comfortable welding.

Moreover, choose an amperage that is at least the same as your welder, or a little bit higher.

For example, if your welding projects require mostly 100 amperes, go for a 150-ampere torch.

Otherwise, your torch could overheat, leading to failure or even hurting you.

3) Hose Length

Hose length (or torch’s lead) is also a must-checked feature fabricators should consider.

It depends largely on the characteristics of your welding project.

- Longer hose: enables you to move around your shops easily without carrying the welder with you.

- Shorter hose: gives you better control over your welding movement.

4) Head Style

The torch’s head style includes Flex Head (mentioned earlier in this article), Flex Lock and Fixed Head.

- With Flex Head, you can easily adjust your head to various angles to fit your intended direction. This head style is suitable for projects with many welding positions.

- With Flex Lock, your torch’s head has the ability to rotate 360 degrees and locked into a desired angle. Thanks to this great feature, Flex Lock torches are very popular in the market and obviously more expensive.

- With Fixed Head, the torch is fixed to a preset angle. Torches with this feature are cheaper, but are only suitable for simple welding projects.

5) Durability

Buying a TIG torch should be a long-term investment.

Thus, you need to check for the torch’s durability.

A durable torch is built from high-quality metal, usually brass.

Apart from the torch itself, pay attention to the strength of the hose and their accessories.

A simple tip when purchasing a TIG torch online is to go through the product reviews from customers to know if your intended torch is durable or not.

6) TIG Welder Options

Last but not least, check available options of your TIG Welder to choose the most suitable torch for it.

One typical example is to look for the solenoid valve in your welder.

If there is no such option in your welder, then you should consider purchasing a torch that has a gas valve in it (remember the variant “V”?)

Other options to go through include the current (AC/DC), the arc starting style, etc.

Once you understand your welder, let’s pick up a torch that matches with its features.

4 Best models of TIG Torch in 2020

This section is made based on my experience and reference to reviews online!

There is no COMMERCIAL PURPOSE here.

So, with that in mind, let’s jump to our first candidate.

1) Weldtec Speedway SW-320SA-25DX Deluxe TIG Torch Kit

This TIG torch from Weldtec is considered the best model in the current market.

Details about this torch is summarized in the following table:

| Specification | Advantage | Disadvantage |

| Silver-brazed copper material allows for higher welding capacity.Protection layer from silicone rubber helps insulate electricity and prevents overheat.Long hose length (25 ft) enables easy moving around, without dragging the welder together.Design of torch handle greatly assists fabricators during welding. | Unique water-cooling mechanism: allows for longer welding time.High-quality material: increases torch’s durability.Flexible design of torch handle: prevents hand fatigue. | Very expensive (up to $320) |

2) CK FL150 Air-Cooled TIG Torch Kit

CK Worldwide is very famous for their high-quality torches, especially ones for pipe welding.

FL150 Torch is one of them.

The following table will help you know more about this product:

| Specification | Advantage | Disadvantage |

| Medium hose length of 12.5 ft, suitable for both indoor and outdoor projects.Power rating of 150 amperes, ideal for light welding tasks.Equipped with Flex Lock (360-degree rotation), allows for great flexibility. | Flex Lock variant: enables welding with unique angles, and avoids hand fatigue.Firm design: ensures higher durability. | More expensive than most torches in the market. |

3) WeldingCity TIG-17FV-12R Torch

If you are having difficulties with your budget but still need a good torch for operation, 17FV-12R Torch from WeldingCity is a good choice.

Let’s further explore this torch model with the following table:

| Specification | Advantage | Disadvantage |

| Air-cooled torch with power rating of 150 amperes maximum, suitable for light welding projects.Equipped with a Flex Head and a Valve (you can tell from the name 17FV), enables for higher flexibility and continuous operation.Medium hose length of 12.5 ft.Included additional kit, such as: 12-ft nylon cable cover with a zipper, a gas separate twist connector, and a power cable connector for Miller TIG Welder. | Flex Head design: provides maximum tilting angle of 135 degrees with extra comfort.Compact design: ensures smooth performance and high accuracy. | Limited adjustment options to modify. |

4) Masterweld WP20-25R Tigmaster TIG Torch

Last candidate on our Top 4 list is a water-cooled torch from Masterweld.

This model is mainly built for professional welders, but newbies can also use and learn from it.

Let’s uncover its feature right below:

| Specification | Advantage | Disadvantage |

| Equipped with a durable zipper to protect the hoses from damage and dirt.Simple design, suitable for even beginners to the industry.Special water-cooling mechanism ensures longer lifespan of the torch.Long hose length of 25 ft, gives welders extra freedom in moving around.Included additional accessories, such as: cable cover and adapter, 1/16-inch tungsten, aluminum cap, collet, colet body and back cap. | Ready-to-use kit: all you need to do is put them together.Long hose: adds flexibility for welders. | Hose material is not very durable.Torch head is Rigid, which may be hard to handle in small spaces. |

Conclusion

Congratulations to you for making this far!

We have gone through every basic thing there is to know about TIG torch – your welding magic wand, from what a TIG torch is, to its structure and features.

If you want to dig deeper into the subject, let’s have a look at other advanced materials we listed in the Reference below.

But if you want to explore more about TIG welding in general, don’t miss out interesting topics from our other articles!

frequently asked questions for Tig Torch

Reference

- A Crash Course on What Makes Up a TIG Torch. Eastwood. Retrieved 12 July 2020.

- TFS: All About TIG Torches. The Fabrication Series. Retrieved 12 July 2020.

- Welding for Dummies. Steven Robert Farnsworth. [2010]

- Welding Principles and Practices (5th Edition) – McGraw Hill Education. Edward R.Bohnart. [2017]