Shielding Gas is one unique feature of Tungsten Inert Gas (TIG) welding.

In this article, you can explore about:

- Different types of shielding gas used for TIG Welding.

- The reason behind the application of shielding gas in TIG Welding.

- A question list about key factors in choosing proper shielding gas for TIG Welding.

Let’s waste no time and discover about shielding gas “TIG-ether”!

What gas is used for TIG Welding?

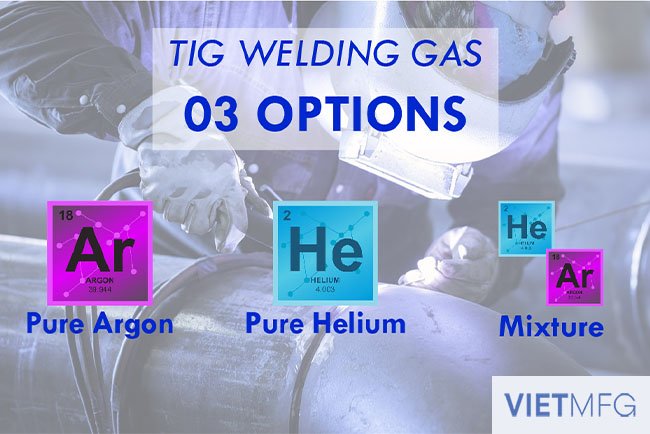

Basically, when it comes to TIG Welding, fabricators have three types of shielding gas to choose.

They are: pure argon (Ar), pure helium (He), and a mixture between the two.

Generally speaking, three shielding gases above can be applied for all materials in TIG Welding.

However, shielding gas selection is crucial as each gas type can give you unique features for each material.

1. Pure Argon (Ar)

Pure Argon is by far the top choice for TIG Welding gas, since it can be applied to various types of material.

The use of Pure Argon can enhance your TIG welding projects in the following ways:

- It shields your welds very well, as the gas is heavier than air, so it can cover the welding area more completely.

- It helps you avoid burning through thin materials.

- It provides very consistent arc at the start of your welding.

- It enhances welding precision by creating a narrower arc. This improves arc stability and removes the burden of cleaning action.

- It requires lower power/ voltage during TIG welding.

- It is more affordable with lower cost.

However, one disadvantage of using Pure Argon is that: It cannot operate with high voltage power, and thus requires more welding time.

Does Pure Argon gas expire?

Pure Argon will NOT expire when being compressed inside the pressurized cylinders.

Just like other shielding gases, Pure Argon is stored in these cylinders (compressed at 2,200 psi – pounds per square inch) and sold at every welding store.

2. Pure Helium (He)

Pure Helium is another option for fabricators to use in TIG Welding.

Using Pure Helium has the following advantages:

- It allows TIG welding at higher voltage setting, which reduces welding time.

- It produces higher heat inputs, which is suitable for dealing with thick materials.

Unfortunately, Pure Helium has certain “minus points”:

- It is more expensive, compared to Pure Argon.

- It provides unstable arc at the beginning of your welding session.

In short, it is only suitable to choose Pure Helium if you are in a hurry and need to finish your TIG welding project as soon as possible.

3. Mix between Argon and Helium

A mix between Argon and Helium is used in TIG welding to combine the benefits of both shielding gases.

A mix can both produce higher heat inputs (Helium’s benefits) while maintaining the consistent arc start for your project (Argon’s benefits).

The proportion of each gas type in the mix depends on the your demand for the welding:

- If you want hotter arcs, you can add more Helium. However, this will decrease your stability in arc start.

- If you want to start your welding with more stable arcs, then add more Argon. And this will obviously lower your heat inputs.

A 50-50 mix (50% Argon and 50% Helium) is the favorite choice of many fabricators for TIG welding.

This balanced mix not only allows hotter arc welds but also produces a more consistent arc start.

However, because of the additional heat, you need to be more careful in controlling the weld. Otherwise, you might burn through your workpiece.

4. Other gas options for TIG Welding: Hydrogen & Mix between Hydrogen – Argon

Hydrogen and A Mix between Hydrogen – Argon are two other options of shielding gases used in TIG Welding.

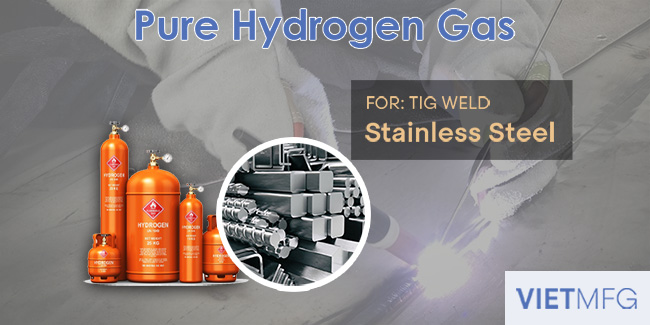

Hydrogen

This shielding gas helps increase the heat input and penetrate into the metal more deeply.

Hydrogen is mainly used when it comes to TIG Welding Stainless Steel.

You can check out our other article about TIG welding stainless steel HERE.

Mix between Hydrogen and Argon

Adding Hydrogen (around 10 percent in proportion) to Argon can help increase the fluidity of weld pool.

The mix can also improve the weld bead appearance.

This special mix is mainly used in TIG Welding for austenitic stainless steel.

5. How about other shielding gas types for TIG Welding?

You may wonder why other gases cannot be used (or can be used in special cases only) for TIG welding.

For TIG welding, only inert gases are allowed, as reactive gases will ruin your workpiece.

This section will clarify those questions and provide a broader view for you about shielding gases.

Can you TIG weld with CO2?

You cannot TIG weld with CO2.

The answer is a big NO!

The reason is that CO2 contains oxygen, and this substance can cause oxidation and ruin your weld.

If your metalwork is oxidized (or if your filler rod is, instead), your weld will be a big fail.

Can you TIG weld with Nitrogen?

YES! You can certainly TIG weld with Nitrogen.

However, Nitrogen MUST be used in combination with Argon, and only applied for a specific type of stainless steel called “duplex”.

Duplex means the mix between two common types of stainless steel: Austenitic and Ferritic.

In-depth information about stainless steel is further discussed in another article of ours HERE.

Can you use the same gas for MIG and TIG?

You cannot use the same gas for MIG and TIG welding.

TIG welding depends solely on inert gas for a quality finish and faces no oxidation.

If those shielding gases are applied in MIG welding, the finished weld will become a mess.

Why do you need gas for TIG Welding?

1. Can you TIG weld without gas?

The answer is NO! Without shielding gas, you simply cannot perform TIG welding.

If you use no gas in TIG welding, your tungsten electrode will be disintegrated due to the lack of protection from the gas.

Thus, the shielding gases (argon, helium, hydrogen, mixtures, etc.) have very important functions in the success of TIG welding.

2. Functions of TIG Welding gas

The most important role of shielding gas in TIG welding is to protect the tungsten electrode and the weld pool from contaminants in the air (oxygen, CO2, etc.)

This protection allows for a cleaner and higher quality TIG weld.

Reactive gases, as well as gases that contain Oxygen, are not allowed in TIG welding.

Such gases would cause reaction or oxidation to the tungsten and/ or the weld pool.

The use of inert gases in TIG welding also helps with the following advantages:

- It creates a more concentrated arc flame with higher heat inputs.

- It produces deeper penetration for strong and thick welds.

- Some gas types can be used specifically in TIG welding thin materials, or give your workpiece special properties (corrosion-resistance, strength, hardness, etc.)

Important question list before choosing suitable TIG shielding gas

1. What is the material of your metalwork?

Your shielding gas selection depends on the material of your metalwork, which means for example, TIG Welding Aluminum requires different gas setting compared to TIG Welding Stainless Steel.

Important factors for choosing suitable TIG shielding gas are summarized in the following table:

| MATERIAL | RECOMMENDED GAS | FEATURES |

| Carbon steel | ArgonHeliumArgon – Helium Mix (75-25 or 50-50) | Provides best puddle control.Produces high speeds, but low gas flows.Improves penetration, highest speeds. |

| Stainless steel | ArgonArgon – Helium Mix (75-25 or 50-50)Hydrogen – Argon Mix (2% or 5% Hydrogen) | Provides excellent puddle control and penetration.Produces higher heat input and welding speed. Requires low gas flows, and minimizes undercutting. |

| Aluminum | ArgonHeliumArgon – Helium Mix (75-25 or 50-50) | Allows best arc start, good cleaning action.Higher weld penetration and speed.Deepest weld penetration and highest weld speeds. |

| Nickel and Copper Nickel Alloys | ArgonHeliumArgon – Helium Mix (75-25 or 50-50) | Provides excellent puddle control and penetration.Produces higher heat input and faster travel speeds.Creates highest heat input for heavy metal sections. |

2. What is the optimal flow rate for your gas?

Understanding about Shielding Gas Flow Rate

Shielding Gas Flow Rate refers to the volume of gas coming out of the TIG torch nozzle in a specified time period.

Shielding Gas Column is another term that is often used to describe the continuous flow of gas between the TIG torch and the weld pool (but since TIG shielding gases are invisible, we just cannot see visually).

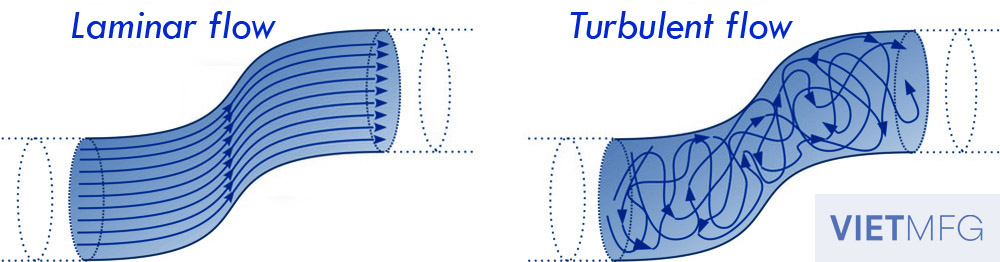

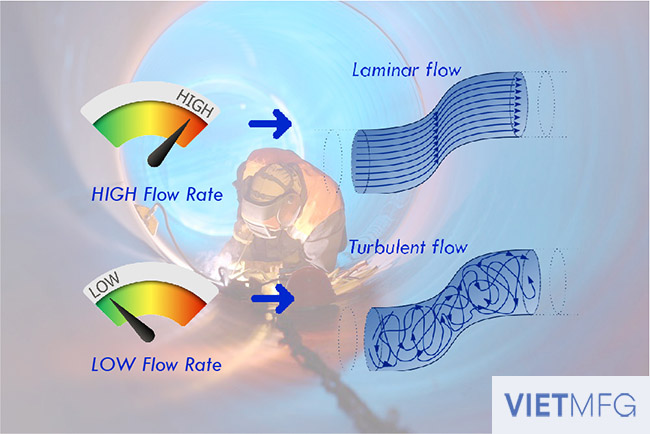

There are two patterns of Shielding Gas Column:

- A laminar flow (MORE desirable): With this flow, shielding gas is flowing in a more controlled and stable manner, with no mixing of other gases in the air.

- A turbulent flow (LESS desirable): With this flow, other gases in the environment can be sucked into the Shielding Gas Column, resulting in the contamination of the tungsten electrode and/ or the weld.

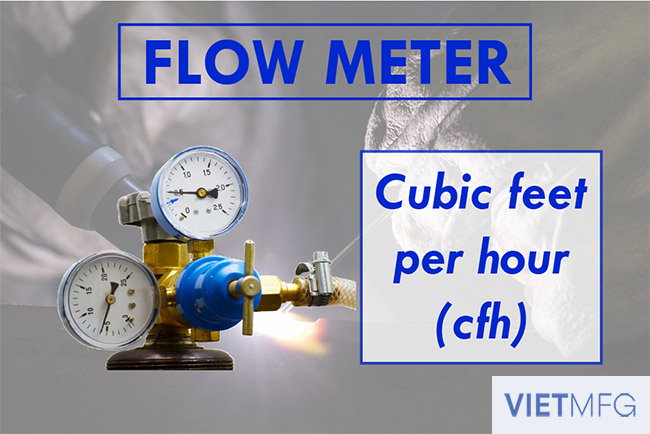

Measurement of Shielding Gas Flow Rate

This flow rate of shielding gas is regulated by a special equipment, called flow meter, and is measured in cubic feet per hour (cfh).

Remember to place the flow meter closest to the welder for the most accurate result.

What happens when we increase/ decrease Shielding Gas Flow Rate

When we configure the Shielding Gas Flow Rate, we will change the Shielding Gas Column as well.

- If Shielding Gas Flow Rate increases, the Shielding Gas Column becomes more “turbulent”, and thus contaminates your weld and/ or tungsten. It could also lead to porosity (small holes) in your weld.

- If Shielding Gas Flow Rate decreases, the Shielding Gas Column becomes more “laminar”, and thus enhances the protection function of the gas.

By now, you would think a lower flow rate is better in protecting your TIG welds.

However, that is NOT necessarily true.

Because if the flow rate is too low, your shielding gas column could be disturbed and not be continuous anymore, and that would potentially contaminate your weld and/or tungsten as well.

Therefore, to reach the desirable “laminar” flow, use the lowest flow rate possible for each type of weld project.

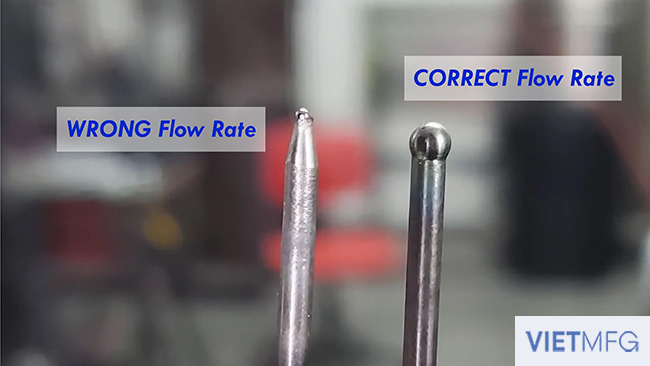

How to know whether we are setting the right Shielding Gas Flow Rate

One simple tip to know whether we are setting the right Shielding Gas Flow Rate is by checking your tungsten electrode after welding:

- If your electrode’s tip is smooth and rounded, you are setting the right level of Flow Rate for your weld.

- If the electrode is deformed by any means, you are using the incorrect Flow Rate for your weld.

For TIG welding, the ideal range of Shielding Gas Flow Rate is between 10 and 35 cfh.

However, at the start of your TIG welding session, it is recommended to set your flow meter at 12 to 15 cfh.

Watch out for the WIND!

Wind can seriously disturb your Shielding Gas Column during the TIG welding.

Therefore, it is recommended to perform TIG welding in indoor areas, such as your garage or welding store.

In addition, you can use a device called windscreen to block the wind, so that it would not mess up with your Shielding Gas Column.

3. What is the correct setup among equipment?

Before TIG welding your projects, make sure your shielding gas cylinder is set up correctly.

Normally, there are two hoses:

- The first hose will connect your gas cylinder to the flow meter.

- The second hose will run from the flow meter to the TIG welder.

The second hose can be equipped with a solenoid valve that can be switched on/ off to control the gas flow.

When switching the solenoid valve on, the shielding gas will travel to the TIG torch and be ready for being discharged.

The TIG torch sometimes contains a gas valve as well to better control the flow rate.

4. What are safety notices for using shielding gas?

Since shielding gases are invisible and contained in pressurized cylinders, using them carelessly can burn or harm fabricators.

Thus, fabricators must follow safety instructions during weld operation.

Here are some safety instructions offered by The National Ag Safety Database (NASD):

- Inspect equipment for leaks at all connections using approved leak-test solutions.

- Inspect hoses for leaks and worn places.

- Replace bad hoses.

- Protect hoses and cylinders from sparks, flames and hot metal.

- Use a flint lighter to ignite the flame.

- Stand to the side (away from the regulators) when opening cylinder valves.

- Open cylinder valves very slowly to keep sudden high pressures from exploding the regulators.

- Only open the acetylene cylinder valve 1/4 – 3/4 turn; leave the wrench in place so the cylinder can be quickly closed in an emergency.

- Open and light acetylene first, then open and adjust oxygen to a neutral flame.

- Close the acetylene torch valve first when shutting off the torch (a “pop” might occur as the oxygen “blows out” the flame, but this eliminates the possibility of the flame burning up the acetylene line).

- When finished, close cylinder valves, bleed the lines to take pressure off regulators, then neatly coil hoses and replace equipment.

- Have a fire extinguisher easily accessible at the welding site.

Conclusion

That’s it!

We have gone through some fundamental information about Shielding Gas for TIG Welding, from the three main gas options, to the gas function and how to have a suitable gas selection.

Please note that this topic is applied for TIG welding only!

The concept of Shielding Gas in welding as a whole is a much wider topic, which will be discussed further on our site.

As usual, if you are eager to learn more about TIG welding in general, don’t miss out our other articles.

frequently asked questions for Tig Welding Gas

Reference

- Gas Welding Safety. National Ag Safety Database (NASD). Retrieved 22 July 2020.

- Shielding the Weld. Sandvik Group. Retrieved 23 July 2020.

- Different types of Welding Gas: MIG VS. TIG & More. Cromweld. Retrieved 23 July 2020.

- Proper Shielding Gas Coverage Is Key to Success in GTAW. Miller. Retrieved 23 July 2020.

- Frequently Asked Questions: TIG Gases. Praxair. Retrieved 23 July 2020.

- Why You Can’t Use the Same Gas for MIG and TIG Welding. Welding Mastermind. Retrieved 23 July 2020.

- Welding for Dummies. Steven Robert Farnsworth. [2010]

- Welding Principles and Practices (5th Edition) – McGraw Hill Education. Edward R.Bohnart. [2017]