To deliver high versatility in the farming operation, screw conveyor design is one essential element worth looking at.

This article will provide you with the following key contents:

● Overview of CEMA’s material classification code.

● Basic characteristics of bulk materials.

● Factors and considerations of screw conveyor design.

Wait no more! Let’s set the ball rolling!

Material Classification Code Chart (CEMA)

CEMA (Conveyor Equipment Manufacturers Association) has established standards for trough loading based on material classification codes.

The code consists five sections:

| No. | Major class | Characteristics | Designation |

| 1 | Density | Bulk density, loose | Actual lbs/ft3 |

| Very fine | A200, A100, A40 | ||

| Fine | B6 | ||

| Granular | C1/2, D3, D7 | ||

| 2 | Size | ||

| Lumpy | D16, DX (X – actual maximum size) | ||

| Irregular | E | ||

| Very free flowing | 1 | ||

| Free flowing | 2 | ||

| 3 | Flowability | ||

| Average flowability | 3 | ||

| Sluggish | 4 | ||

| Mildly abrasive | 5 | ||

| 4 | Abrasiveness | Moderately abrasive | 6 |

| Extremely abrasive | 7 | ||

| Builds up and hardens | F | ||

| 5 | Miscellaneous properties or hazards | Generates static electricity | G |

| Decomposition – Deteriorates in storage | H | ||

| Flammability | J | ||

| Becomes plastic or tends to soften | K | ||

| Very dusty | L | ||

| Aeration – Fluidity | M | ||

| Explosiveness | N | ||

| Stickiness – Adhesion | O | ||

| Contaminable | P | ||

| Degradable, size breakdown | Q | ||

| Gives off harmful or toxic gas or fumes | R | ||

| Highly corrosive | S | ||

| Mildly corrosive | T | ||

| Hygroscopic | U | ||

| Interlocks, mats or agglomerates | V | ||

| Oils present | W | ||

| Packs under pressure | X | ||

| Very light and fluffy – may be windswept | Y | ||

| Elevated temperature | Z |

Along with learning about screw conveyor overview, grasping CEMA codes would give you a more in-depth look into the work of this versatile machine.

Factors Influencing Screw Conveyor Design

The Material Classification Code Chart from CEMA also outlines typical characteristics such as abrasiveness, corrosiveness, and flowability of the granular particulates to be conveyed.

In designing screw conveyors, it is important to fully aware and deeply analyze these traits, in order to select the most suitable machines for your business.

The following part will further discuss the characteristics of Abrasiveness and Miscellaneous properties or hazards.

Abrasive Particulates (6 & 7)

Extreme wear and tear may happen to screw conveyor compositions when transporting abrasive particulates.

Therefore, abrasion-resistant alloys are ideal choices for various screw conveyor types.

Some suggestions for such materials include Tri Braze or Chromium Carbide overlay.

One important note when dealing with abrasive particulates is to slow down the screw conveyor speed, as well as lower its trough loading.

Builds Up and Hardens (F)

Certain conveying items build up and harden in the screw conveyor’s trough.

They also have a tendency to suck up moisture and pack under pressure.

The closer the clearance between trough and screw is, the better the prevention of build-up incident in the trough.

Additionally, high screw conveyor torque is needed to cut through the hardened particulates.

Other cutting tools such as tungsten carbide are also suitable.

Generates Static Electricity (G)

During the conveying process, as the screw augers spin and shake the bulk materials, static electricity can be generated.

Therefore, grounding the trough of the screw conveyor is highly recommended.

By grounding the trough in multiple locations, it could help eradicate static electricity efficiently.

Additionally, lowering both screw conveyor speed and trough loading can greatly help, too.

Decomposition – Deteriorates in Storage (H)

For long periods of storage time, decomposition and deterioration can happen to bulk materials.

Therefore, engineers must consider discharging and processing all particulates stored in hoppers (or silos) before they decompose or deteriorate.

Moreover, knowledge on the characteristics of specific conveying items is very important, whether they are easily decomposed or not.

Flammability (J) and Explosiveness (N)

Whenever oxygen and a source of ignition are available, flammable and explosive items will burn.

To prevent the emergence of ignition sources, screw conveyors should be fabricated with non-sparking materials.

Screw conveyor’s tight troughs or housings equipped with shaft seals are also required to keep oxygen outside the machine.

Regarding the inside of the screw conveyor, engineers can consider filling with inert gas, such as nitrogen.

Becomes plastic or Tends to Soften (K)

A number of particulates are excessively sensitive to temperature variations, or pressure changes.

The auger spinning can generate frictional force and soften the bulk materials.

Thus, conveying items such as food products must be carefully transported.

For such bulk materials that tend to soften or become plastic, it is suggested to lower trough loading and screw conveyor speed.

Very Dusty (L)

Many conveying particulates can become dusty and escape from the screw conveyors.

These dusty objects can be hazardous and in some extreme cases, explosive.

Depending on the hazard level, designs of screw conveyor troughs or housings may vary.

However, for dusty materials, one important requirement is to seal off the screw conveyors completely with special shaft seals.

Aerates and Becomes fluid (M)

During the conveying process, fluidizing materials will aerate and tend to flood like water.

Then, trough loading will increase and cause the flooding of downstream mechanical components.

To mitigate the possibility of bulk material aeration, it is recommended to lower trough loading and screw conveyor speeds.

Stickiness – Adhesion (O)

Viscous (or sticky) particulates are very difficult to convey from one location to another, as they are highly moisture and oiled.

There is a high chance that sticky materials stick to the screw conveyor’s centre pipe where the auger is placed.

To deal with viscous particulates, ribbon flighting is an ideal selection.

Shaftless screw conveyors are an even better choice for handling these bulk materials.

Contaminable, Affecting Use (P)

Preserving the original condition of bulk materials is the most important requirement in conveying.

If, for any reason, bulk materials are polluted with foreign particulates, they will lose value and thus, the conveying process is meaningless.

Therefore, ensuring screw conveyors are completely sealed off with special shaft seals is necessary.

Engineers can consider utilizing hanger bearings to protect bulk materials from contaminators.

Degradable, Affecting Use (Q)

Conveying degradable particulates (items which are easily broken down) is difficult as the particulates could lose their value.

Besides low trough loading and low speed, large size of screw conveyors are also suggested for better transportation.

Gives off Harmful or Toxic Gas or Fumes (R)

Chemical particulates have a tendency to exert hazardous vapors or dusts, which are a threat to human health.

Once again, sealing off screw conveyors proves to be important, in order to enclose toxic conveying items.

It is also recommended to design screw conveyors to curb internal pressure or explosion.

Hygroscopic (U)

Hygroscopic means the absorption of moisture, and sometimes leads to the state of being contaminated.

Therefore, vapor-tight covers are essential for conveying hygroscopic bulk materials.

In some cases, maintaining a consistent temperature for materials is needed, via insulation, using a jacket for the screw conveyor troughs, or even filling troughs with dry gas.

Interlocks, Mats or Agglomerates (V)

Bulk materials that tend to mat together and resist the conveying process have interlocking traits.

Therefore, to compensate for such resistance, higher screw conveyor torque is required.

Conveying path needs to be throughout, with no obstruction.

Thus, hanger bearings in such situations are not advised.

Instead, shaftless screw conveyors can be an optimal selection for interlocking particulates.

Oils Present (W)

Conveying materials that are oil-contained is troublesome, as they tend to be sticky and adhere to the screw augers or screw conveyor troughs.

Therefore, similar to viscous materials, selecting ribbon augers or using no auger at all (shaftless screw conveyors) can result in better performance for the conveying process.

Packs Under Pressure (X)

With moisture content and pressure come into play, certain materials will pack together and become compressed.

Special screw conveyors equipped with “breaker bars” can greatly assist in the breaking of material lumps and reduce packing incidents.

And obviously, to do that, screw conveyors require more horsepower and torque drive.

Very light and fluffy (Y)

Very light and fluffy materials refers to those weighing less than 15 lbs/ft3.

These bulk materials are likely to aerate when being conveyed.

To tackle aeration problem, choosing a screw conveyor with larger diameter is suitable.

Additionally, the setting of low trough loading and slow screw conveyor speed is highly recommended.

Elevated Temperature (Z)

To cope with extremely hot bulk materials, screw conveyors should be fabricated with high temperature stainless steel alloys.

Trough loading degree: Suggestions from CEMA

Trough loading is the depth of bulk material in the trough of a screw conveyor and is measured in percent when compared to a full trough. a full trough is considered 100-percent full.

Recommended trough loadings of 15, 30 and 45-percent were developed based on the characteristics of bulk materials.

The recommended trough loading for a screw conveyor is a function of the density, abrasiveness and flowability of bulk material.

For a given capacity, screw conveyor size and speed is determined by trough loading percentage.

According to CEMA, the degree of trough loading is based on the material being delivered.

From CEMA’s material class code, trough loading degree can be determined, with details as follow:

| Material Class Code | Degree of Trough loading | |

| A-15 | ||

| A-25 | ||

| B-15 | 45% | |

| B-25 | ||

| C-15 | ||

| C-25 | ||

| A-35 | E-15 | Above 30% (30% A) |

| A-45 | E-25 | |

| B-35 | E-35 | |

| B-45 | E-45 | |

| C-35 | ||

| C-45 | ||

| D-15 | ||

| D-25 | ||

| D-35 | ||

| D-45 | ||

| A-16 | C-36 | |

| A-26 | C-46 | |

| A-36 | D-16 | |

| A-46 | D-26 | |

| B-16 | D-36 | Below 30% (30% B) |

| B-26 | D-46 | |

| B-36 | E-16 | |

| B-46 | E-26 | |

| C-16 | E-36 | |

| C-26 | E-46 | |

| A-17 | C-37 | |

| A-27 | C-47 | |

| A-37 | D-17 | 15% |

| A-47 | D-27 | |

| B-17 | D-37 | |

| B-27 | D-47 | |

| B-37 | E-17 | |

| B-47 | E-27 | |

| C-17 | E-37 | |

| C-27 | E-47 |

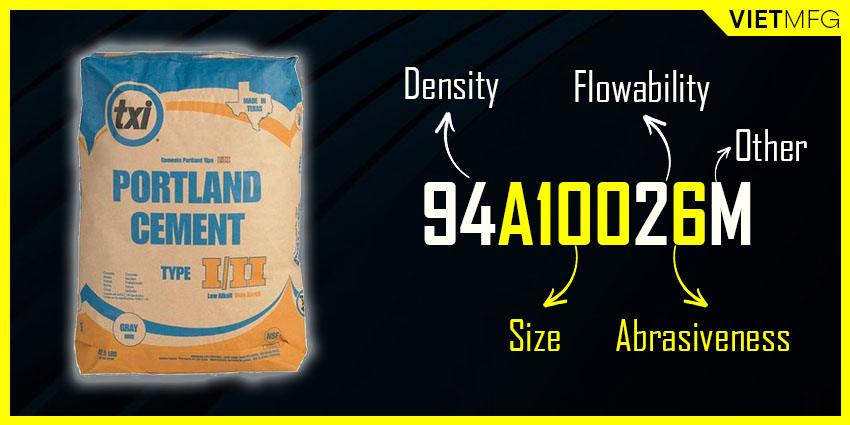

For example, Portland cement’s code is 94A10026M. This code can be broken down as follows:

94: the material’s density, 94 lbs/ft3.

A100: the material’s size, very fine (~ 0.0059’’ and under).

2: the material’s flowability, free flowing (flow function from 4 to 10).

6: the material’s abrasiveness, moderately abrasive (index from 18 to 67).

M: miscellaneous properties, aeration – fluidity.

Therefore, Portland cement is described as free flowing and moderately abrasive. Together with its size as very fine, CEMA recommends a trough loading of no more than 30 percent for such particulate.

For a more durable operation life of screw conveyors, CEMA suggests reducing the machines’ capacity and velocity when transferring mildly to extremely abrasive materials.

Considerations When Designing A Screw Conveyor

When designing a screw conveyor, manufacturers must make clear certain factors: the application, the type of material to be conveyed (based on CEMA’s material class codes), material load volume, projected using frequency, and whether there are any other necessary processes for the conveyor to perform.

These details are useful in the decision making process for certain criteria, like: conveying materials, orientation, add-on components and energy supply.

Energy supply can either come from an electric motor or from nearby components.

To best fit your requirements, screw conveyor engineers may customize and present you with multiple options.

For instance, they can insert components such as: flexible discharge hoses, integral bag dump hoppers, inspection ports, and even make your screw conveyor movable.

Overview Characteristics Of Bulk Material

Conveyor size, speed and horsepower requirements are directly affected by the following characteristics of the conveyed bulk material.

1. Maximum Particle Size

Particle size is mainly measured in inches. In some cases, a mesh screen gauge is also used in the measurement process.

2. Bulk Density

Conveying capacity for screw conveyors and screw feeders is calculated volumetrically in cubic feet per hour (ft3/hr).

The bulk density of the bulk material is needed in order to convert capacities given in tons per hour or pounds per hour to cubic feet per hour.

Accurate bulk density information is needed for selecting the proper screw conveyor or screw feeder.

3. Trough Loading

Trough loading is a prime factor in determining conveyor size and is based on the maximum depth at which bulk materials will flow through a screw conveyor without causing undue wear on the conveyor components, such as screws, hanger bearings, couplings shafts and troughs.

The recommended trough loading is lower for abrasive bulk materials in comparison to non-abrasive bulk materials.

4. Material Factor (MF)

Material factor represents the resistance of a bulk material to be conveyed and is used for calculating screw conveyor horsepower.

The material factor may vary for screw feeders.

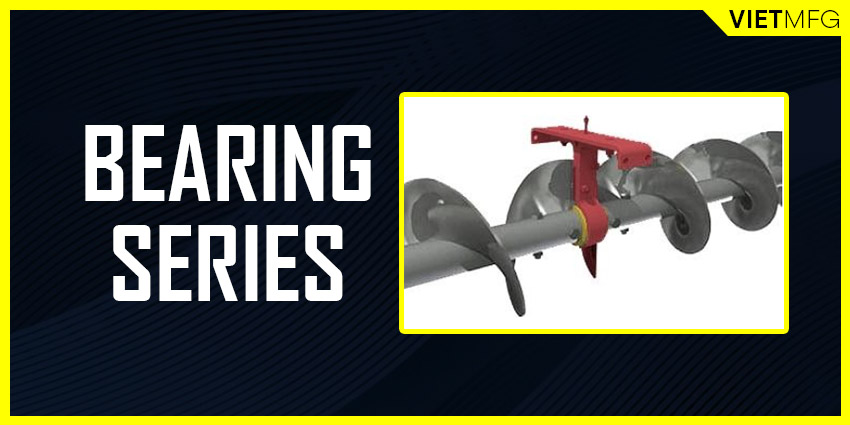

5. Component/ Bearing Series

The recommended component series assists in the selection of screw conveyor components for a given bulk material.

In general, lighter duty construction is acceptable for free flowing and nonabrasive bulk materials.

Heavier duty construction is recommended for sluggish and abrasive bulk materials.

The alphabetical code refers to the general component series and the numerical code refers to hanger bearing recommendations.

6. Abrasiveness, Corrosiveness, Flowability, And Special Characteristics

Each of these characteristics affects how the material reacts to and moves through the screw conveyor.

Last Note

I hope this article about screw conveyor design has provided you with in-depth information on the structure of this versatile machine.

In addition, there is also detailed explanation on the characteristics of bulk materials that are usually handled by screw conveyors.

If you are looking for additional information regarding this agricultural machine, feel free to check out other related articles.

FAQs

Link Out And Prosper!

1. Screw Conveyor design calculations. PowderProcess. Retrieved on April 08th, 2021.

2. Screw Conveyor Example. KWS. Retrieved on April 08th, 2021.

3. All About Screw Conveyors – Types, Design, and Uses. Thomasnet. Retrieved on April 08th, 2021.

4. Screw Conveyor Bulk Material Characteristics. KWS. Retrieved on April 08th, 2021.