Although being an ancient design by Archimedes to use in farming (pumping irrigation water), screw conveyor is still a vital manufacturing machine nowadays, especially in bulk handling for short distances.

In this screw conveyor overview, you will gain more understanding on this versatile farming machine with the following contents:

- Definition, history and application of a screw conveyor.

- Detailed composition of a screw conveyor.

- Operating mechanism of a screw conveyor.

- Certain safety remarks of a screw conveyor.

Let’s start right away!

What is a screw conveyor?A screw conveyor has a second name, called auger conveyor.

Its function is to transport and/ or elevate fluid or granular particulates, such as food and drink.

Some examples include food waste, wood chips, cereal grains, municipal solid waste, etc.

Therefore, the equipment has various applications in bulk material handling industries, ranging from industrial minerals, agriculture (grains), pharmaceuticals, chemicals, pigments, plastics, cement, sand, salt and food processing.

The equipment is also used for measuring the flow rate (metering) from storage boxes, or for adding minor controlled quantities of trace elements such as pigments to granular particulates or powders.

Bill of Materials of Screw Conveyor

A typical screw conveyor comprises up to 15 distinct mechanical parts, which are outlined in the table 1.

Table 01: Screw Conveyor’s Bill of Materials.

| Item | Description |

| 1 | Screw (flight, auger) |

| 2 | Screw (flight, auger) with bare pipe at discharge |

| 3 | Coupling shaft |

| 4 | Hanger with bearing |

| 5 | Trough end |

| 6 | Trough end for Screw Conveyor Drive |

| 7 | Trough |

| 8 | Trough with Discharge Spout |

| 9 | Seal |

| 10 | Bearing |

| 11 | Tail shaft |

| 12 | Flanged cover |

| 13 | Flanged cover with inlet |

| 14 | Buttstrap |

| 15 | Screw Conveyor Drive Unit |

Components of a screw conveyor

Despite having numerous screw conveyor types, a standard machine acquires four (04) main compositions:

- Screw blade (flight, auger) [a]

- Trough (tubular housing) [b]

- Cover [h]

- Screw conveyor drive unit [f]

Firstly, screw blade (or otherwise called flight, auger) is a rotating helical component, located within a tube or a trough.

When operating, the blade will spin around its shaft, which connects the two ends of the equipment (the drive unit at one end, and the tail shaft at the other), and move the materials along the way.

The flight’s rotating speed determines the machine’s volume transfer.

In other words, the faster the screw blade spins, the more materials the screw conveyor delivers within a determined time period.

In industrial application, such rotation rate is regulated to supply a calculated pace or quantity of materials into a production procedure.

Secondly, trough (or tubular housing – used when a screw conveyor is inclined over 15-degree) is the container covering the screw blade, and is the platform accommodating the particulates.

The component is the backbone of the machine, linking inlet to discharge spout. Also, trough loading is one important element in screw conveyor design.

All troughs and tubular housings are available in carbon steel construction, as well as abrasion-resistant steels, stainless and hot-dipped galvanized steel.

Thirdly, cover is stationed over the trough and secured in place to furnish a firm enclosure for the bulk material and to provide protection for personnel operating and maintaining the equipment.

Standard lengths are 10-feet (for 4, 6, and 9-inch diameter screw conveyors), and 12-feet (for screw conveyors 12-inch and larger in diameter).

Last but not least,the drive unit is the heart of the screw conveyor.

The high performance capability of the gear guarantees durable operating life and prevents costly idling time of the machine, especially with inclined conveyor lines whose particulates are easily fallen back.

How does screw conveyor work?

Screw conveyor is a volumetric conveying machine. Simply put, the equipment is designed to discharge materials or products at a predetermined flow rate from inlet to discharge spout.

Normally, bulk materials are put into the inlet through another conveyor line or metering equipment, such as rotary valves, grinders, screw feeders, etc.

Among such metering devices, screw feeders are worth-mentioned because of its similarities with screw conveyors.

Screw feeders are also designed to transfer bulk materials.

However, unlike screw conveyor lines, screw feeders’ inlets are always 100 percent filled and linked with a hopper, silo or bin.

Screw conveyors operate based on the principle of Archimedes’ screw.

The principle states that: when a rotating screw blade or flight (auger) is accurately positioned inside a cylinder (or a tube), the component can transfer water in a determined direction.

Additionally, every resolution the flight spins, it will allow space for new materials to enter the tube.

The rotating velocity of a screw conveyor is calculated in cubic feet per hour (ft3/hr).

Other measurement units include pounds per hour (lbs/hr), tons per hour, or bushels per hour.

- 1 ft3/hr = 46.15 lbs/hr

- 1 ft3/hr = 0.0283 ton/hr

- 1 ft3/hr = 0.8035 bushel/hour

As screw conveyors receive bulk materials from the inlet at a controlled rate, the cross-sectional trough loading is normally less than 100 percent flooded. In fact, trough loading rate depends on the materials fed from the inlet.

Application of screw conveyors

Screw conveyors greatly help move, or convey materials such as food, packages, or products from one place to another.

In most cases, the equipment is used to perform automated or semi-automated finishing or manufacturing lines.

Dry items are ideal materials to be conveyed by screw conveyors between different areas, like vehicles, hoppers, and silos.

For that function, screw conveyors are found in a huge range of industries, from agriculture, food processing to construction. Specifically:

- In agriculture, screw conveyors are utilized as an essential part of machinery to transport dry, loose objects such as animal feed to different locations.

- In food processing, screw conveyors conveys dry ingredients used in the food making process, such as nuts, salt, and flour.

- In construction industry, screw conveyors are applied to combine wet and dry ingredients to produce plaster or cement.

History of screw conveyors

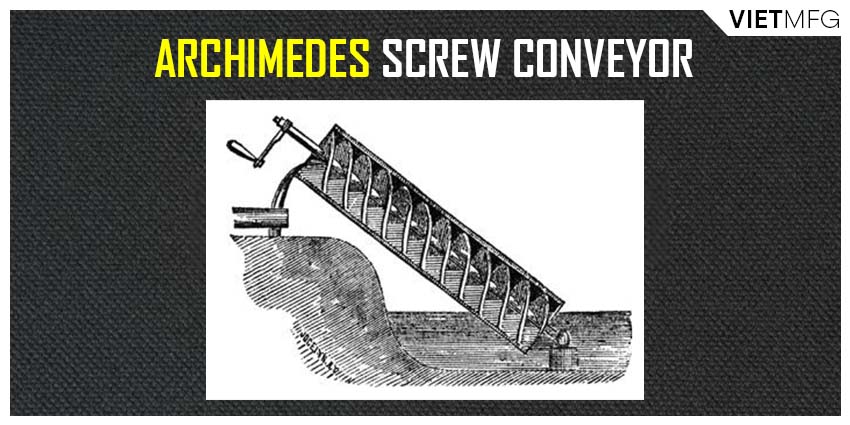

The long history of screw conveyors dates all the way back to the 3rd century BC, during the period of Ancient Egypt.

The first record of a water screw, or the Egyptian screw, comprises tubes wound round a cylinder.

As the whole unit spins, water is elevated within the spiral tube to higher positions.

The initial water screw design was believed to have been utilized for water lifting from the Nile river.

Some researchers are confident that this device used to supply water for the Hanging Gardens of Babylon, one of the Ancient World’s Wonders.

Moreover, evidence of Egyptian screw’s application is found during Assyrian King Sennacherib’s reign (704-681 BC): the scene of casting water screws in bronze is incarnated in a cuneiform inscription.

Strabo, a classical author, also supports this evidence whose stories depict Egyptian using water screws to irrigate for the Hanging Gardens.

The screw pump was later introduced to Greece, by an ancient Greek scientist and mathematician named Archimedes, after his trip to Egypt circa 234 BC.

Although the screw pump was not initially designed by Greek scientists, Archimedes’ screw brings about an efficient process for water supply and removal, especially water removal from boats and ships, for Western people.

Archimedes screw is the foundation upon which many developments throughout history are based.

For instance, in 1405, German military engineer Konrad Kyeser outlined in his book, Bellifortis, an Archimedes screw featuring a crank mechanism.

The screw conveyors as we see today were innovated between the late 19th and mid-20th century.

During the period, screw conveyors were mostly applied in agriculture. The gadgets are so popular among farmers, and often referred to as grain conveyors.

Also, screw conveyors are used in construction to convey items such as cement.

Throughout the 20th century, many manufacturers and constructors have incorporated the use of stainless steel and other advanced materials into making equipment such as screw conveyors.

Auger conveying lines nowadays acquires a high automation degree.

Thanks to many technology upgrades, engineers can expand their application scope of screw conveyors, including extremely heavy-duty tasks.

Safety and compliance standards for screw conveyors

In the United States (US), every screw conveyor entering the market must receive certification from Conveyor Equipment Manufacturers Association (or in short, CEMA).

CEMA is a trade association established in 1933, with its members including top manufacturers of screw conveyors worldwide.

Thanks to the comprehensive expertise of its members, CEMA is capable of creating publications for standards and technical advancements in the screw conveyor producing industry.

In addition to that, your conveyor should pass the requirements of your field. For example, a food processing crew conveyor should pass the FDA (Food and Drug Association) standard.

Likewise, a grain conveyor should pass the standards of the USDA (United States Department of Agriculture). To learn more, please seek further specialized consultation.

The table below shows common problems arising from screw conveyors’ operation, together with their causes and remedial solutions:

| No. | Problem | Cause | Remedial solution |

| 1 | Accelerated wear and tear of augers | Auger diameter too small | Increase auger thickness. Use abrasion resistant materials or hardfacing. |

| Excessive RPM or trough loading | Reduce speed. Consult CEMA document to determine recommended speed and trough loading | ||

| 2 | Hanger bearing failure | Inaccurate Alignment | Realign trough assembly and hangers |

| Unsuitable trough loading and speed | Consult CEMA document to determine recommended speed and trough loading. | ||

| Improper hanger material | Consult CEMA document to determine recommended bearing material. | ||

| Extreme bearing wear | Replace hanger bearing. | ||

| 3 | Premature trough failure | Trough thickness too light | Increase trough thickness. Use abrasion resistant material. Consult CEMA document to determine recommended trough thickness. |

| Screw Deflection | Consult CEMA Document to Determine Proper Pipe Size and Screw Length. | ||

| Bent Screw | Straighten or Replace Screw. | ||

| 4 | Shaft Hole Elongation | Increase number of Coupling Bolts | |

| Conveyor Subject to Frequent Stop/Start | Cease Frequent Stop/Start. Increase Bearing Capacity of Shaft and/or Increase Number of Coupling Bolts. | ||

| Frequent Overloads | |||

| 5 | Drive Shaft Breakage | Excessive Torque | Consult CEMA Document Proper Torque Rating |

| 6 | Motor Overload | Motor Undersized | Consult CEMA Document to Determine Proper Horsepower Requirements |

| Upset Loading Condition | Empty Trough, Control Feed and Operate Under Screw Conveyor Specifications. | ||

| 7 | Trough End Bearing Failure | Bearing Contamination | Upgrade or Replace Seal. Change to Outboard Bearing. |

| Shortage of Lubrication | Lubricate in Accordance with Maintenance Section of this Document. | ||

| Improper Shaft Runout | Check Screw Straightness and Replace as Necessary. | ||

| 8 | Coupling Shaft Breakage | Excessive Torque | Consult CEMA Document to Determine Proper Torque Rating. |

| Inaccurate Alignment | Realign Trough Assembly and Hangers in Accordance with Assembly Section of this Document | ||

| Extreme wear and tear of Coupling Shaft | Replace Coupling Shaft |

Last Note

This article on screw conveyor overview has outlined all the fundamental information about the incredible farming machine.

Of course, there are more in-depth topics surrounding screw conveyors. Therefore, do not hesitate to check out our other writings.

FAQs

Link Out And Prosper!

1. Screw Conveyor Engineering Guide. KWS. Retrieved on April 07th, 2021.

2. Archimedes’ screw. Wikipedia. Retrieved on April 07th, 2021.

3. Screw conveyor. Schrage Conveying Systems. Retrieved on April 07th, 2021.