Let’s dive deeper into the world of screw conveyor specification in this article. Spoiler alert that the writing will contain detailed formulas and calculations regarding the specifications of this versatile machine.

Specifically, this article will provide you with the following in-depth topic:

- Screw conveyor capacity

- Screw conveyor horsepower

- Screw conveyor torque

Without further ado, let’s start off right away!

Screw Conveyor Capacity

1. How to define Capacity of Screw Conveyor?

Capacity refers to the volume per hour of a conveying particulate via a screw conveyor. Screw conveyor diameter is determined by multiple factors including capacity.

2. Calculation of Screw Conveyor Speed

Using the formula below, the exact conveyor speed (S) can be calculated:

Nomenclature:

S = Conveyor Speed

CFH = Capacity in Cubic feet per Hour (ft3/hr)

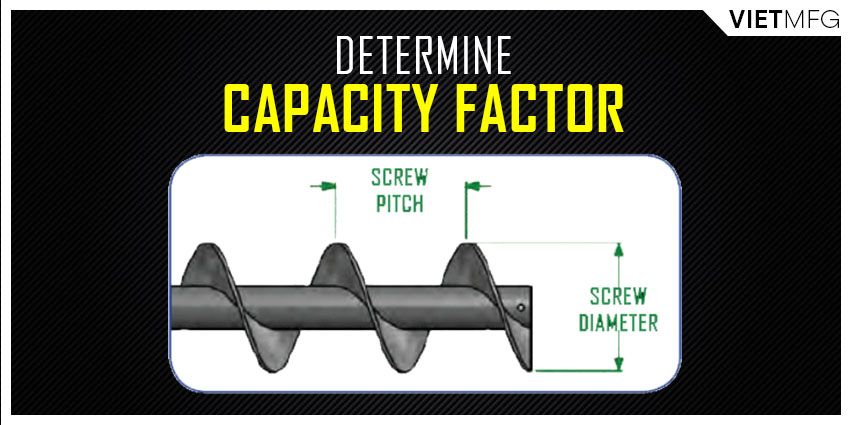

3. Capacity Considerations for Special Pitches

Screw conveyor capacity is influenced when the pitch is lowered from standard full pitch. Lowering the auger pitch can hamper the capacity.

For instance, a 1/2 pitch carries 1/2 the capacity of a full pitch screw at the same level of trough loading and speed.

Selection Capacity (SC) is the capacity adjusted for special pitch, applied in the selection of the screw conveyor diameter. Calculation of special screw conveyor capacities is as follows:

Nomenclature:

SC = Selection Capacity

CFH = required Capacity in Cubic feet per Hour (ft3/hr)

CF = Capacity Factor

| Capacity factors for Special Pitches | ||

| Pitch | Description | Capacity Factor |

| Standard | Pitch = Diameter | 1.00 |

| Short | Pitch = 2/3 Diameter | 1.50 |

| Half | Pitch = 1/2 Diameter | 2.00 |

| Long | Pitch = 1-1/2 Diameter | 0.67 |

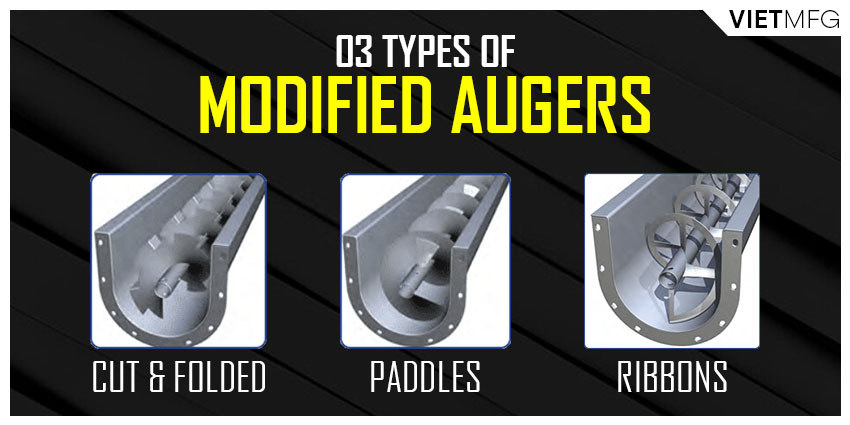

4. Capacity Considerations for Modified Augers

Screw conveyor capacity is also influenced by installing modified auger types, such as cut auger and cut and folded auger.

The application of modified augers reduces conveying capacity.

Capacity factors for Modified Augers are shown below for various auger types and trough loading.

Table 01: Capacity Factor For Cut/ Cut And Folded Augers

| Augers Type | Conveyor Loading | ||

| 15% | 30% | 45% | |

| Cut auger | 1.92 | 1.57 | 1.43 |

| Cut and folded auger | X | 3.75 | 2.54 |

Table 02: Capacity Factor For Paddles Augers

| Paddles per pitch | 1 | 2 | 3 | 4 |

| Factor | 1.08 | 1.16 | 1.24 | 1.32 |

Table 03: Capacity Factor For Ribbon Augers

| Ribbon Screw Diameter | Conveyor Loading | ||

| 15% | 30% | 45% | |

| 4 | X | X | X |

| 6 | 1.32 | 1.52 | 1.79 |

| 9 | 1.34 | 1.54 | 1.81 |

| 12 | 1.11 | 1.27 | 1.50 |

| 14 | 1.27 | 1.45 | 1.71 |

| 16 | 1.55 | 1.69 | 1.90 |

| 18 | 1.33 | 1.53 | 1.80 |

| 20 | 1.60 | 1.75 | 1.96 |

| 24 | 2.02 | 2.14 | 2.28 |

| 30 | 2.16 | 2.29 | 2.44 |

| 36 | 3.27 | 3.37 | 3.70 |

Screw Conveyor Horsepower

1. How to define Horsepower of Screw Conveyor?

Generally speaking, horsepower refers to the rate at which work is carried out.

In the case of screw conveyors, horsepower is the power needed for the machine to safely transport a bulk material a fixed distance.

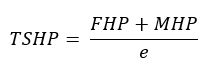

2. Total Shafts Horsepower (TSHP)

The term horsepower relating to the operation of a screw conveyor is called Total Shaft Horsepower (TSHP).

As there are a wide array of screw conveyor types, it is very essential to manufacture a screw conveyor with sufficient horsepower in order to prevent downtime and production loss.

TSHP is the combination of Friction Horsepower and Material Horsepower, divided by the drive efficiency.

- Friction Horsepower (FHP): Friction Horsepower is the horsepower needed to operate a screw conveyor under empty condition. Friction from the bearings, seals and other moving components generate resistance. Therefore, adequate horsepower is very important to win the friction.

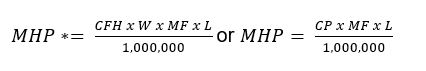

- Material Horsepower (MHP): Material Horsepower is the horsepower needed to move granular particulates the full screw conveyor’s length. The Friction Horsepower and Material Horsepower calculations are shown below:

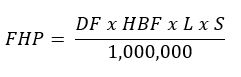

3. Calculation of Screw Conveyor Horsepower

Calculation of Total Shafts Horsepower (TSHP)

Calculation of Friction Horsepower (FHP)

Calculation Material Horsepower (MHP)

* If Calculated Material Horsepower is less than 5HP, it should be corrected for potential overload.

Nomenclature:

FHP = Friction HP (HP required to drive conveyor empty)

DF = Conveyor Diameter Factor

HBF = Hanger Bearing Factor

L = Conveyor Length (ft)

S = Conveyor Speed (RPM)

MHP = Material HP (HP required to convey bulk material)

CFH = Conveyor Capacity (ft3/hr)

W = Bulk Density (lbs/ft3)

MF = Material Factor (from Bulk Material Table)

CP = Capacity (lbs/hr)

TSHP = Total Shaft HP

e = Drive Efficiency (Typical value of 0.88 is used for a shaft mount reducer/motor)

4. Diameter Factor (DF)

The Diameter Factor (DF) is an important figure which represents the frictional resistance of the weight of the screw conveyor for various diameters.

| Diameter Factor Table (DF) | |

| Diameter | Factor |

| 4 | 12 |

| 6 | 18 |

| 9 | 31 |

| 12 | 55 |

| 14 | 78 |

| 16 | 106 |

| 18 | 135 |

| 20 | 165 |

| 24 | 235 |

| 30 | 377 |

| 36 | 549 |

5. Hanger Bearing Factor (HBF)

The Hanger Bearing Factor (HBF) is an empirical value determined over many years of testing and represents the frictional resistance of the hanger bearing for various types of hanger bearing materials.

| Hanger Bearing Factor Table (HBF) | |

| Bearing Type | Bearing Factor |

| Ball, Roller or none | 1.0 |

| Bronze or wood | 1.7 |

| Plastic, Nylon, UHMW or Teflon | 2.0 |

| Hard Iron or Stellite | 4.4 |

6. Material Factor (MF)

The Material Factor (MF) is an important figure representing the frictional resistance of the conveying items.

As the material density increases, normally the Material Factor increases.

The reason is because denser bulk materials are more difficult to transport from one location to another.

7. Corrected Material Horsepower

The drive unit for a screw conveyor is operated together with a gear reducer and motor. However, it is not always 100-percent well-functioning.

There are absolutely frictional losses in the gear reducer. Drive efficiency (e) then falls between 85 and 95-percent.

The calculated horsepower of a screw conveyor may need to be modified, so the drive unit will have more horsepower and torque available to compensate for upset conditions, especially in case of large lumps being transported.

The Corrected Material Horsepower Factor (or Overload Factor) is used to increase the Total Shaft Horsepower (TSHP) of a screw conveyor when the calculated Material Horsepower (MHP) is under 5 HP.

In short, increasing TSHP in the screw conveyor designing process allows the machine to conquer most upset conditions, reducing downtime and production losses.

Screw Conveyor Torque

1. How to define Torque of Screw Conveyors

Torque is the twisting force originated from the screw conveyor’s drive unit.

Torque is transferred through the drive shaft of the drive unit to the conveyor screw and converted into force for moving particulates.

2. Calculation of Torque of Screw Conveyors

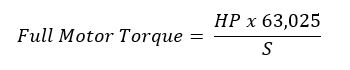

Full Motor Torque is the maximum torque exerted by the drive unit. The equation for full Motor Torque is shown below:

Nomenclature:

HP = Nameplate Horsepower of the motor on the screw conveyor

S = Conveyor Speed

Torque is measured in inch-lbs. for screw conveyor components.

The torque rating of the drive shaft, coupling shafts, coupling bolts and conveyor screw must be able to stand firm against full Motor Torque without failing.

Maximum torque ratings are based on a safe stress value for the specific material of construction.

The screw conveyor components will have an infinite life under normal operating conditions.

Screw Feeder Capacity

Before diving into the calculator of screw feeder capacity, let’s have a look at the following table:

Table 1: Screw Feeder Capacity (ft3/hr/RPM) for standard pitch screws

| Dia- meter | Standard Pipe Sizes | |||||||||

| 1.00’’ | 1.25’’ | 1.50’’ | 2.00’’ | 2.50’’ | 3.00’’ | 3.50’’ | 4.00’’ | 5.00’’ | 6.00’’ | |

| 4’’ | 1.56 | 1.44 | 1.35 | |||||||

| 6’’ | 5.30 | 4.97 | 4.41 | |||||||

| 9’’ | 18.90 | 18.49 | 17.85 | 16.25 | ||||||

| 10’’ | 26.28 | 25.73 | 25.02 | 23.49 | ||||||

| 12’’ | 45.28 | 44.42 | 42.99 | 41.89 | ||||||

| 14’’ | 71.67 | 70.15 | 68.73 | 67.10 | ||||||

| 16’’ | 106.35 | 104.72 | 102.86 | |||||||

| 18’’ | 153.06 | 151.20 | 149.10 | 146.50 | ||||||

| 20’’ | 209.50 | 204.00 | 201.00 | 197.50 | ||||||

| 24’’ | 366.40 | 363.60 | 356.40 | 348.60 |

The above table reveals screw feeder capacity which is measured in feet per hour per RPM. These data are directly related to standard pitch flightings only.

Screw feeder capacity is determined by two main elements: (i) the diameter of standard pitch flighting (first column), and (ii) the standard pipe size (second row).

Each figure in the above table can be used as a reference. By that I mean, if you are utilizing a diameter that is not listed in the table, you can calculate that screw feeder capacity in direct ratio to one of the chosen referencing data.

For example, from Table 1, it is obvious that a screw feeder with 9’’ diameter of standard pitch flighting on a 2.50’’ standard pipe size will have a capacity of 17.85 ft3/hr/RPM.

Now, with that same screw feeder, if you use a 3’’-diameter standard pitch flighting, simply take that reference figure and divide it by three (as 9’’-diameter is three times of 3’’-diameter), and you will have the desired number of 5.95 ft3/hr/RPM.

However, remember that this figure of screw feeder capacity is only theoretical. The actual value will be influenced by other elements, such as material characteristics, variations in pitch and diameter resulting from producing tolerances.

Screw Feeder Speed

To calculate the screw feeder speed, you simply divide the desired capacity (ft3/hr) by the standard figure in Table 1 (ft3/hr/RPM). Thus, the final unit of screw feeder speed is RPM, which stands for Revolutions Per Minute.

Compared to screw conveyor speed, screw feeder speed should be slower in order to achieve the optimal efficiency.

In addition, essential allowances must be prepared in advance for slippage of the material in the screw feeder.

Last Note

Capacity, horsepower, and torque are three fundamental elements of screw conveyor specification. All three items have been clarified clearly and comprehensively in this article.

After reading through my mini series about screw conveyor, I truly hope you have gained essential knowledge regarding the topic, from screw conveyor overview to other in-depth related issues.

Do not hesitate to browse through other articles about screw conveyor to have a more all-rounded understanding about this agricultural machine.

Link Out And Prosper

1. Screw Conveyor Horsepower. KWS. Retrieved on April 10th, 2021.

2. Screw Conveyor Torque. KWS. Retrieved on April 10th, 2021.

3. Screw Conveyor Capacity. KWS. Retrieved on April 10th, 2021.

4. Catalog and Engineering Manual. Screw Conveyor Corporation. Retrieved on April 10th, 2021.