If you search the keyword “flux core welding aluminum[1] ” on any search engine, you will find quite a lot of information related to it, just like every other flux core welding of other metals.

However, it is a completely different story with flux core welding aluminum. Let’s decode that mystery with me in this article, by discussing about:

- The big question: Can we perform flux core welding aluminum?

- The reason why flux core aluminum welding wire is unavailable.

- Some alternative solutions for flux core welding aluminum.

Alright, matey! Let’s go solve some mysteries!

The Big Question: Can Flux Core Welding Aluminum Be Performed?

I will be straightforward to you.

The answer is NO.

We cannot perform flux cored arc welding[2] on aluminum because: there is no flux core aluminum welding wire available for this process.

Well, you might think that my answer is just based on rumours.

Not at all, mate!

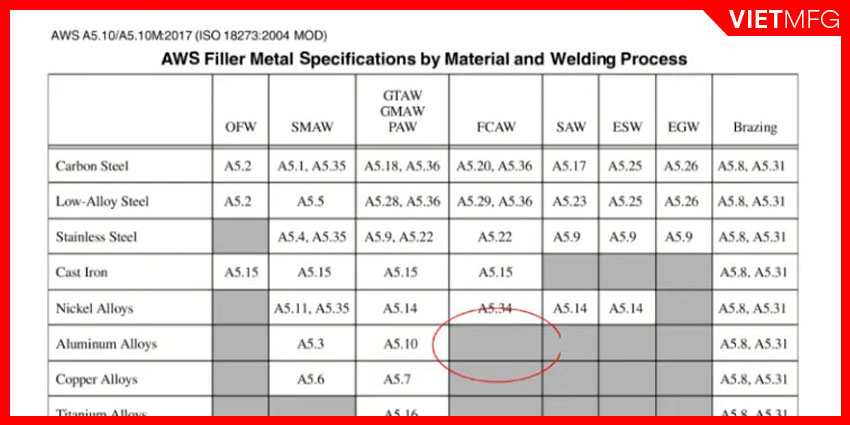

This is confirmed officially by the American Welding Society (AWS) in their document “AWS A5.10/A5.10M:2017 (ISO 18273:2004 MOD): Welding Consumables—Wire Electrodes, Wires and Rods for Welding of Aluminum and Aluminum Alloys— Classification”.

You can see for yourself in the snapshot I provide below.

When AWS leaves it blank for flux core aluminum welding wire, it’s high time to accept the defeat. This flux core wire[3] is a total myth.

What Can You Find When You Search For Flux Core Aluminum Welding Wire?

The keyword “flux core aluminum welding wire” might have led you here.

It might lead you to tons of diverse information and advertisements, with that exact keyword in their titles.

Be careful with what you search for, as not all welding wires you see are actually aluminum flux core welding wires (or gasless aluminum MIG welding wires).

Well, most of the time, you will end up seeing one of the three wire types:

- Solid Aluminum Wire: This wire type is very easy to recognize. If you see a little tag saying “Argon recommended”, then this is it. Most of the time, real flux core welding wires require no external shielding gas (FCAW-S).

- Soldering Aluminum Wire: This is a totally different type of aluminum wire, which will be discussed more in another related article.

- Brazing Aluminum Wire: As the name refers, this wire type is applicable for brazing machines. It can also be used in a furnace with strictly controlled air supply, or in an induction brazing procedure, or even with propane gas torch. All of this application proves that the wire type is not for flux core welding aluminum at all.

Of course, those rods cannot be used with your gasless flux cored welders[4] , as this thing needs Argon to function. Try one of those, and you will have to replace your flux cored welders soon.

Although flux core aluminum welding wire is a myth (at least I spoil it for you now), people still search for this keyword a lot on Google.

This is the reason why many websites put on incorrect content with such keyword to get more traffic to their pages. They just take advantage of this search trend.

So, the truth is there is no such thing as flux core aluminum welding wires. However, when you search for them on search engines, you will find tons of results, all of which are fake and unhelpful.

Why Does No Flux Core Aluminum Welding Wire Exist?

I guess your natural response to the information above is a big “WHY?”. At least I have that question when I realize the sad truth as well.

After accepting the truth, I began to learn about the reason behind the wires’ unavailability.

In my opinion, there are four main problems relating to quality and usability issues that make flux core aluminum welding wires unavailable.

1. Difficult To Feed

Aluminum is so soft.

Even with solid aluminum wire, it is still very challenging to feed it in the welding process.

Then, with a hollow aluminum flux core wire, how difficult can you imagine it to be?

The inevitable result would be the wire getting crushed and jammed.

It would take a very specialized drive system to feed the aluminum flux core wire, as the basic wire drives are unable to do the task.

2. Low Quality Flux Compositions

Because of aluminum’s special characteristics, it is impossible to use fluxes dedicated to flux cored welding stainless steel[5] or mild steel on it.

Then, how about aluminum fluxes?

Well, aluminum fluxes are excessively corrosive. This is a serious problem for both the fabricators and the environment.

Moreover, these aluminum fluxes are hygroscopic and can greatly absorb water from the air. This will ultimately lead to poor weld quality and generate a great deal of spatter.

3. The Essence Of Flux Core Arc Welding

Flux core arc welding can create tons of spatter, even on steel workpiece.

With aluminum, its fluid nature at high welding temperatures can magnify the issue.

The tremendous amount of molten metal spattering out of the weld puddle would degrade the final weld quality and aesthetic.

4. The High Reactivity Of Aluminum

What amazes me is that the flux core aluminum welding wire had once been tested in the laboratory, but was never commercialized.

In the real world, there are too many variables that require strict control. On the other hand, aluminum is so reactives. That is the reason finding a suitable flux shield to cover aluminum is almost “mission impossible” outside of the laboratory.

Is It Possible To Use Normal Flux Cored Welding Wire To Weld Aluminum?

It is a big NO. You cannot use flux core welding wire of other material to perform flux core welding aluminum.

FCAW and aluminum will never match, and the final joint is gonna look terrible.

Tons of spatter will be generated. Eventually, your contact tip would be clogged up. Your welder might be burnt, as well.

So in short, do not waste your time trying normal flux cored welding wire to weld aluminum.

Alternative Solutions For Flux Core Welding Aluminum

By now, we all reach one common conclusion that it is impossible to perform flux core aluminum welding. Thus, let’s look at other alternative solutions for this issue.

The first solution is aluminum soldering:

- This is a process that employs no shielding gas at all.

- Within the world of soldering, there are many different methods.

- With some methods, you may find a propane gas torch being used to melt the solder material onto the joint.

- However, as the soldering iron cannot generate enough heat to weld aluminum, the ultimate weld result will not be a firm joint.

- Also, to perform aluminum soldering, the aluminum joint must be extremely clean. With dirt and contamination, your solder would not stick.

The second alternative for flux core welding aluminum is brazing:

- If aluminum soldering melts the solder at low heat, brazing does the opposite by melting the metal at a higher temperature.

- The filler metal used for this process is sometimes referred to as “flux core aluminum welding wire for brazing”, which can cause some misunderstanding. Remember, this wire is not designed to use in an electrical arc (while flux core wires are).

- Brazing process utilizes a gas flame torch (not a MIG torch).

- Similar to soldering, your aluminum pieces need to be extremely clean as well.

Other alternative options include TIG and MIG process, which I had discussed in detail before.

Conclusion

That is everything about it, flux core welding aluminum.

And the final answer to our big question is “No, you cannot perform flux core welding aluminum”, simply because there is no such thing called “flux core aluminum welding wire”.

So, instead of cramming yourself to find that unicorn rod, let’s focus on other alternative solutions that I have provided in the article.

I hope it helps you one way or another.

Reference

- Flux Core Aluminum Welding Wire: What You Need To Know. WelditU. Retrieved December 30th, 2021.

- Scrambling Desperately For Flux Core Aluminum Welding Wire?. Weld It Myself. Retrieved December 30th, 2021.

- Aluminum Workshop: The Burning Question Behind Welding Aluminum With FCAW/SAW. The Fabricator. Retrieved December 30th, 2021.

- Welding Consumables—Wire Electrodes, Wires and Rods for Welding of Aluminum and Aluminum Alloys— Classification. AWS A5.10/A5.10M:2017 (ISO 18273:2004 MOD) An American National Standard.