Flux cored welders[1] are the powerful equipment that every fabricator needs, both hobbyists and professional ones, for their welding jobs.

However, choosing a suitable one for your welding project is not an easy task. Do not worry! In this article, I will:

- Review some of the best flux cored welders for your buying decisions.

- Provide useful guides for picking up suitable flux cored welders.

- Share my top pick.

What are we waiting for? Let’s go shopping together!

What exactly are Flux Cored Welders?

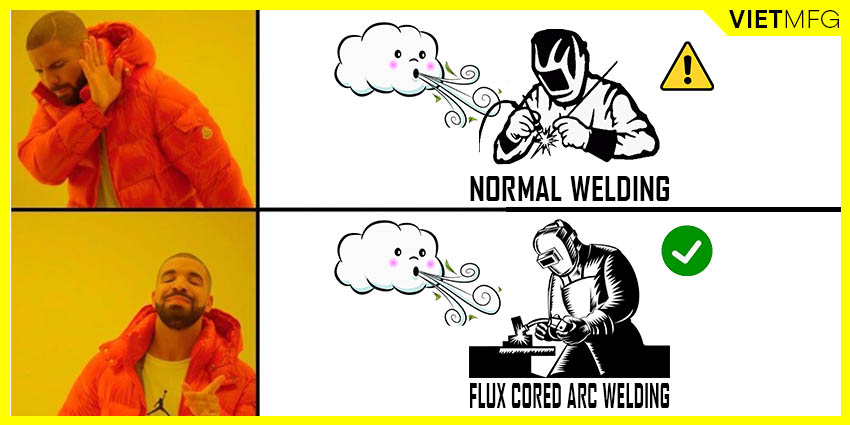

Flux Cored Welders are the engineers’ solution to make welding outside possible, even in windy conditions.

They technically employ continuous wire feed systems just like MIG welders. However, thanks to the special flux cored wires that self-generate shielding gas under high temperatures, flux cored welders require no external shielding gas.

With flux cored welders, you don’t have to worry about a sudden breeze that could ruin your weld. They can produce great results under windy conditions, which is impossible with the usage of MIG machines.

What Are The Best Flux Cored Welders For 2021?

There are many reputable brands that produce flux cored welders. For instance, the most famous one must be Lincoln Electric, with its world-class welding models. YesWelder, Hobart, Eastwood and Forney are also known for their versatile and easy-to-use welders at very affordable prices.

The following list of best flux cored welders for 2021 will only feature products of the above brands. I really hope this list will be informative for you to make a great welder selection in 2021.

- Best Overall: Lincoln Electric Easy MIG 180 Flux Cored Welder

- Best Budget: YesWelder MIG Welder 250A MIG Pro

- Best For Hobbyists: Hobart Handler 140 Flux Cored Welder

- Eastwood MIG 135 Flux Cored Welder

- Forney 140 MP Flux Cored Welder

- Goplus MIG 130 Welder

- Reboot MIG150 Welder

- Forney Easy Weld 299 125FC Flux Cored Welder

- Super Deal PRO Commercial MIG 130 AC Flux Core Wire Automatic Feed Welder

- Hobart Handler 210 Flux Cored Welder

Flux Cored Welders’ Comparison Chart For 2021

Before going through all the details about each flux cored welder in my recommended list, I have prepared a small comparison table for you. It is the necessary preparation before you go on with the article.

Table 01: Flux Cored Welders’ Comparison Chart

| Best Flux Cored Welders | Input Power | Output Range | Duty Cycle |

| Lincoln Electric Easy MIG 180 Flux Cored Welder (Best Overall) | 240V | 30 – 180A | 30% at 130A |

| YesWelder 250A MIG Pro Welder (Best Budget) | 240V | 20 – 250A | 60% at 250A |

| Hobart Handler 140 Flux Cored Welder (Best For Hobbyists) | 120V | 25 – 140A | 20% at 90A |

| Eastwood MIG 135 Flux Cored Welder | 120V | 25 – 135A | 20% at 90A |

| Forney 140 MP Flux Cored Welder | 120V | 10 – 140A | 30% at 90A |

| Goplus MIG 130 Welder | 110V | 25 – 140A | 15% at 90A |

| Reboot MIG150 Welder | 115V | 30 – 140A | 80% at 200A |

| Forney Easy Weld 299 125FC Flux Cored Welder | 110V | 50 – 120A | 35% at 60A |

| Super Deal PRO Commercial MIG 130 AC Flux Core Wire Automatic Feed Welder | 110/220V | 105A | 15% at 105A |

| Hobart Handler 210 Flux Cored Welder | 120/240V | 25 – 210A | 30% at 150A |

Top 10 Best Flux Cored Welders For 2021

I believe this part is the reason that you came here for. Detailed information on the best flux cored welders in my list will be presented accordingly. I hope you will find your ideal flux cored welder here from my suggestions.

1. Best Overall: Lincoln Electric Easy MIG 180 Flux Cored Welder

Overview

The Lincoln Electric Easy MIG 180 Flux Cored Welder requires a 240-volt power input.

This welder features an internal gas solenoid that helps it functions as a MIG welder as well.

If you are a novice welder and do not know very much of how to set up the welder properly, do not worry. As the machine comes with a settings chart located on the cabinet door.

It is also very simple to operate, with just only two knobs for you to work around. There are five different preset power levels that can be set in a matter of a click.

The wire feed system is adjustable and has a working speed ranging from 50 to 500 inches per minute.

With this Lincoln’s smooth arc starting mode, striking an arc will become easier than ever. Its current range can be set dynamically, running from 30 amperes (to weld the thin 24-gauge sheet metal) all the way up to 180 amperes (to deal with 3/8 inch or 1/2 inch steel plate).

If you have had trouble working with aluminum wire in the past, then you would be grateful with this Lincoln welder, as it is equipped with a precision aluminum wire drive system and housing to get rid of all those aluminum wire feed problems.

However, that would not be very beneficial, as flux cored welding aluminum[2] is currently impossible.

The torch connection is made of brass to prevent current loss and maximize power at the base metal.

Highlighted features

- Output range: 30 – 180 amperes.

- Brass-to-brass torch connection.

- Featuring a precision aluminum wire feed system and housing.

- Dealing well with metal thickness from 24 gauge up to 1/2 inch steel plates.

- Having a 10 foot MIG gun.

Why I like it

- The wire drive system is adjustable.

- Having a settings chart on the cabinet door for novice welders.

- Mounting 4 inch and 8 inch spools.

- Being equipped with an internal gas solenoid for performing the MIG process.

Watch out for

- Having some minor problems with the wire feed system’s inconsistency.

2. Best Budget: YesWelder 250A MIG Pro Welder

Overview

This multi-process welding machine from YesWelder can perform four different processes, including MIG, TIG, Stick and Flux cored arc welding[3] .

It operates ideally with a 240-volt power input, and generates an output range of 20 to 225 amperes.

All sheet metals with thicknesses from 28 gauge to 1/2 inch can be dealt effectively with this welder.

The surprise part lies in its very affordable price.

Upon purchasing this YesWelder model, you will receive an electrode clamp for stick welding as well. Apart from the MIG process with DC current setting, stick welding is a great alternative for aluminum welding.

The machine also received great acclaim for its flux core capability, with three different wire spools included. Lift-type arc initiating function for the TIG process is also a bonus for this machine.

However, the package does not feature any connection for a MIG spool gun to operate, as well as no TIG accessories (such as a TIG torch, a regulator or a heat control pedal).

Highlighted features

- Output current ranging from 20 up to 225 amperes.

- Multi-function welder that can perform TIG, MIG and Stick Welding.

- Capable of welding from 28 gauge to 1/2 inch steel plates.

- Featuring a 10-foot torch connection with a K15 MIG gun.

Why I like it

- The Dinse connector is of high quality (Euro-style).

- Great function of lift-type arc starting.

- Including 3 different wire spools.

- The control panel can be flipped over.

Watch out for

- There are no TIG accessories or regulators that come with the purchase.

3. Best For Hobbyists: Hobart Handler 140 Flux Cored Welder

Overview

If you are a welding hobbyist, you just cannot miss out on this Hobart welder. It is a wonderful combination of user-friendly features for home shop and professional quality.

The welder can run on 120-volt input power, so it can be used at various locations. With an output range of 25 to 140 amperes, the machine can work wonderfully with all steel plates from 24 gauge to 1/4 inch in thickness.

Its basic function is to perform self-shielded flux cored arc welding. However, with a few simple steps, you can convert it to MIG welding with full use of shielding gas. The machine also includes a world-class Miller gas regulator.

This multi-process Hobart welder features both 4-inch and 80-inch wire spools with a solid wire feed drive system.

The compact design increases the machine’ portability, making it easier to move around.

All in all, Hobart Handler 140 is a wonderful selection for every craftsman.

Highlighted features

- Performing both MIG and flux cored arc welding.

- Operating on 120-volt input power.

- Generating 25 to 140 amperes.

- Handling steel plates from 24 gauge up to 1/4 inch of thickness.

- Adjustable wire speed from 40 to 700 ipm.

Why I like it

- Featuring a solid metal wire feed system.

- Having 5 different power settings.

- Having a high quality Miller gas regulator and a 10-foot Miller gun.

Watch out for

- Requiring a wrench to configure the spool tension.

- Sensitivity of the wire feed knob is quite high.

4. Eastwood MIG 135 Flux Cored Welder

Overview

Featuring a quick-release spool design, Eastwood MIG 135 is a popular choice among fabricators. Besides mounting both 2-pound and 10-pound wire spools, the welder is always ready for MIG operations, thanks to the gas regulator and hose included in the package.

The MIG gun that comes with the purchase is of the popular Tweco brand. It is very easy to find replacement parts for this brand’s products, thanks to its huge availability.

However, to run flux core wire[4] , you will need to purchase a separate drive spool designed specifically for the flux core process.

The machine also features a settings chart for your quicker and simpler process switch. The settings can be adjusted infinitely, which is great for modifying your weld quality during the process.

The Eastwood MIG 135 welder can generate up to 135 amperes in output current, which is optimal for penetrating 1/4 inch steel plates. Its lower threshold of 25 amperes allows you to work fine with 24 gauge sheet metals.

Highlighted features

- Requiring 120-volt input power.

- Generating 25 to 135 amperes in output current.

- Featuring Tweco MIG gun.

- Dealing great with steel plates from 24 gauge to 1/4 inch.

Why I like it

- The gas regulator and hose of high quality are available upon purchase.

- Infinitely adjustable settings which allows greater control over weld quality.

- Mounting both 2-pound and 10-pound wire spools.

- Settings chart is provided.

Watch out for

- The drive gear is made of plastic, which is not very durable.

5. Forney 140 MP Flux Cored Welder

Overview

Our next candidate is a 3-in-1 (TIG, MIG and Stick) welder from Forney, named Forney 140 Multi-process.

My first impression about this welder is that the machine is very lightweight (around 25 pounds) and simple to operate. The configuration for wire feed speed and current settings are infinite, which means greater control over weld quality.

This Forney welder works fine with sheet metals from 24 gauge to 1/4 inch of thickness. This is possible because of the wide output range from 10 to 140 amperes.

With Forney welder, flux cored welding stainless steel[5] and other metals become easier than ever before.

Regarding flux cored arc welding, Forney 140 MP is very superior thanks to its Easy Start technology that provides clean and aesthetic welds with deep penetration. The machine also mounts both 4-inch and 8-inch wire spools.

However, if you want to do MIG or TIG with this welder, you have to buy additional equipment. The separate gas regulator and hose are required for MIG, while TIG torch and other related accessories are needed for the TIG process.

One last note is that foot pedal cannot be used with this machine for the TIG process.

Highlighted features

- Featuring a built-in fan.

- Generating 10 up to 140 amperes, which is suitable for welding 24 gauge to 1/4 inch steel plates.

- Adapting the Easy Start technology for Stick welding.

Why I like it

- Very lightweight and easy to use.

- Mounting both 4-inch and 8-inch wire spools.

- Current power and wire feed speed can be infinitely adjustable.

- 3-in-1 design for MIG, TIG and Stick welding processes.

Watch out for

- There are no TIG torches, regulators or gas hoses that come with the purchase.

6. Goplus MIG 130 Welder

Overview

Goplus MIG 130 is a must-have flux cored welding tool. It is portable, versatile and features an automatic wire feed system. The greatest thing about it is its capability to operate in both home shop and professional projects.

The input power required for Goplus MIG 130 welder is 110 volt (or 60 hertz). Upon buying, you will receive an additional 72.5 inch power cord.

Furthermore, the machine is very sturdy and durable, thanks to its stainless steel case and plastic handle.

Highlighted features

- Featuring stainless steel case and plastic handle.

- Having 15% duty cycle at 105 amperes.

- Providing 4 different adjustable levels of current flow.

- Being equipped with 2 fans that cools down the welder during operation.

- Including welding wires and protective masks.

Why I like it

- Very lightweight and durable.

- Great selection for working on steel plates.

- Featuring an overheat protective circuit.

- Having a storage space on top of the machine to keep small accessories.

Watch out for

- Not powered by batteries.

7. Reboot MIG 150 Welder

Overview

This is another 3-in-1 design welder for your potential list, the Reboot MIG 150. It is very versatile and can perform MIG, Stick and Flux cored arc welding. All three different processes are combined in one single welder.

The machine can deal great with material thickness up to 1/3 inch, but it is highly recommended to weld at 1/4 inch thickness only.

What makes this welder stand out is its inverter technology that is very energy efficient. However, this inverter design is relatively new, which is equivalent to unsolved performance issues.

Among my recommended flux cored welders, this Reboot model is by far the most lightweight machine. It weighs just 12 pounds. Thus, you can freely move it around on your own.

Highlighted features

- Featuring new inverter technology.

- Only 12 pounds of weight.

- Performing 3 different welding processes (MIG, Stick and Flux cored arc welding).

Why I like it

- Providing excellent weld quality.

- Exceptionally lightweight and portable.

- Very versatile.

- Capable of dealing with thick metals.

- Energy efficient, thanks to the inverter technology.

Watch out for

- The inverter option is not very consistent.

8. Forney Easy Weld 299 125FC Flux Cored Welder

Overview

Here comes another representative from Forney, a reputable brand for high quality welding machines. This is Forney Easy Weld 299 125FC Flux Cored Welder, an ideal option for novice welders and DIY enthusiasts.

It works fine on 120-volt input power and produces up to 125 amperes of output current. With its capability, this Forney machine can easily weld sheet metals from 24 gauge to 1/4 inch.

Beginners will find this welder very effective for practicing with delicate and thin welds. It utilizes both 2-pound and 10-pound wire spools, which widens your wire choice.

The Forney Easy Weld 299 125FC is designed for self-shielded flux cored arc welding only. It is not equipped with any external shielding gas. Hence, the machine is very portable and safe.

Highlighted features

- Performing self-shielded flux cored arc welding only.

- Requiring 120 volts of input power.

- Generating up to 125 amperes of output current, which works well with steel plates from 24 gauge to 1/4 inch.

- Featuring 6 feet of power cord.

Why I like it

- Extremely portable and easy to use.

- Providing sufficient output power for small projects.

- Safe during welding due to the self-shielded feature.

Watch out for

- Not very portable due to its being bulky and difficult to move around.

9. Super Deal MIG 130 AC Flux Core Wire Automatic Feed Welder

Picture 11 – Super Deal MIG 130 AC Flux Core Wire Automatic Feed Welder.

Overview

Our upcoming welder is designed to serve both commercial and home-scale welding projects.

With its reasonable weight of 38 pounds, the machine is very portable and can be moved around easily. The compact design also proves useful during storage.

This welder features a unique waveform control option that lets you adjust freely for diverse requirements. Ultimately, you will face less spatter and create more fusion depth.

The on/off control of the welding gun makes welding much safer. The machine also has 10 wire feed speeds and 4 voltage controllers for you to choose.

However, the welder is not very suitable for heavy-duty applications, as its many parts are made of PVC. You simply cannot expect great durability from such a material.

Highlighted features

- Operating ideally with 110 volts (or 60 hertz).

- Current range from 50 to 120 amperes.

Why I like it

- Compact design that is easy to move and store.

- Offering various wire feed speeds.

- Emphasizing safety with many protective features.

- Suitable for both repairing and home-scale projects.

Watch out for

- Less compatible due to its massive weight.

10. Hobart Handler 210 Flux Cored Welder

Overview

Our last recommended welder belongs to Hobart. It is Hobart Handler 210 Flux Core Welder.

Its design focuses on being easy for users to operate, but still adapting to industrial standards. It has a wire feed drive system that runs well with solid metal wire. The welder also features a gas solenoid and dual-gauge regulator to make room for the MIG process with shielding gas.

The Hobart Handler 210 works well on either 120-volt and 240-volt input power. Of course, there is an adapter included in the purchase that lets you switch from one power source to another.

With this welder, you can freely adjust among 7 different levels of current settings and 10 wire feed speeds. It can deal with thin sheet metal of 24 gauge, which is popular for auto body work. Gear up the heat and wire speed, and you can weld up to 3/8 inch steel plates.

Hobart machines have a great reputation among steel workers and fabrication specialists. And Hobart Handler 210 is no exception. It can handle both 4-inch and 8-inch wire rolls, with 10-foot leads included.

Highlighted features

- Working well on both 120-volt and 240-volt input power.

- Dealing effectively with sheet metal from 24 gauge to 3/8 inch.

- Featuring 7 different levels of power settings and 10 wire feed speeds.

- Generating up to 210 amperes of output power.

Why I like it

- Drive roller can be changed quickly.

- Long MIG gun with 10 feet long.

- Adapting well with both 4-inch and 8-inch wire spools.

- Featuring a built-in gas solenoid and a gas regulator for MIG welding with shielding gas.

Watch out for

- Requiring a wrench to change the wire spool.

- The gas hose is not of high quality.

Comprehensive Buying Guide On Best Flux Cored Welders

The world of Flux Cored Welders is a vast category with various options. Thus, picking up one model that is suitable for your welding application requires serious consideration. Right here, I have outlined some factors that you should pay attention to during your selection process.

1. MIG Welders Or Flux Cored Welders

Let’s focus, as this one is quite confusing. All MIG machines can run flux cored arc welding, but not every flux cored welder can operate the MIG process.

So ask yourself, whether you will need to run MIG welding in the future or not? Or are you satisfied with flux cored arc welding only?

If you do need MIG in the near future, pay attention to pick a MIG welder. Do not trust the machines’ names. Read their specification carefully, as not all welders having the word “MIG” in their names are true MIG welders.

2. Considering Your Metal Thickness

Your metal thickness is probably the single most important factor in choosing your flux cored welders.

This piece of information is directly related to the machines’ output range. The wider output range is, the larger span of thickness you can weld with the machines.

For example, if you need to weld metal of about 1/4 inch thick, you can choose machines with an output range of 130 – 140 amperes.

If you weld thicker materials (up to 3/8 inch or 1/2 inch thick), the output range of over 200 amperes is required.

Usually, the materials that come with the welders will declare clearly their applicable metal thickness.

3. Paying Attention To Your Input Power

120-volt and 240-volt are the two most popular input power sources that you can find in many flux cored welders. Some models even allow you to operate on either one of them with a converter.

Input power will determine the maximum output current that can be generated. For example, a 120-volt powered flux cored welder can produce approximately 140 amperes maximum. This value is equivalent to welding steel plates of up to 1/4 inch thick.

If your projects demand welding with thick metal, such as pipe fencing or trailer frames, you will need to use 240-volt welders. Or, simply choose a flux cored welder that can function on both input sources.

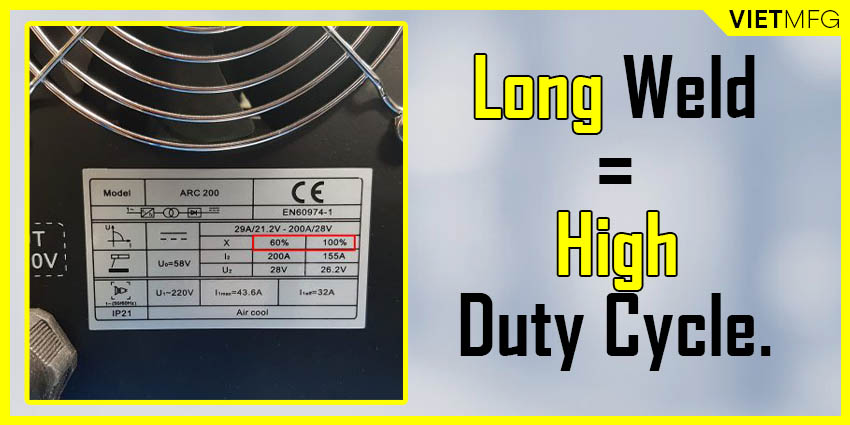

4. Understanding Duty Cycle

The duty cycle of a flux cored welder reveals how much time you can continue to operate the machine before it requires a rest.

For example, if one flux cored welder claims that its duty cycle is 30% at 130A, it means you can weld at 130 amperes for 3 minutes before resting it.

Thus, pay attention to this data, and reflect back on your project requirement. If your project demands a long weld, you had better choose the flux cored welder with a higher duty cycle.

6. Watching Out For The Machines’ Size And Weight

Portability is quite unrelated to technical aspects. However, as flux cored welding can weld outside, the flux cored welders’ size and weight should be considered seriously.

It is best to pick up a machine that is easy to transport around. Its design should be compact, too, so that it can fit in tight areas.

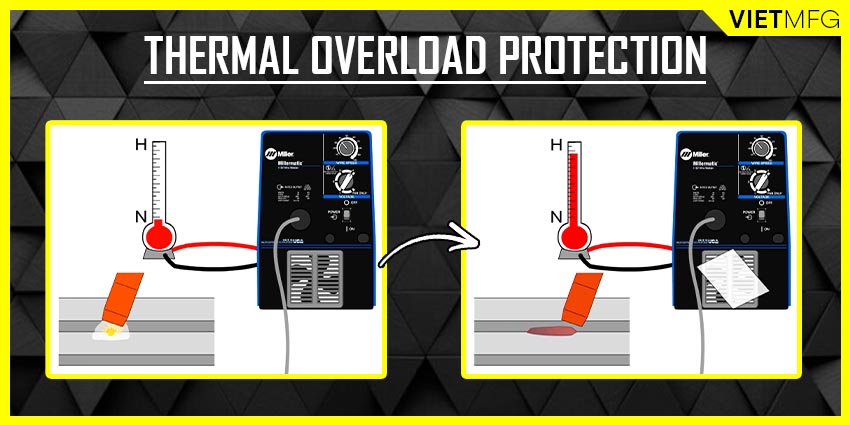

7. Thermal Overload Protection

The thermal overload protection feature is utilized to prevent the welding torch from being overheated. It will automatically shut the welder down when overheat starts. Thus, this mechanism helps enhance the durability of the flux cored welders.

Once the welder cools down, the thermal overload protection feature is switched on again. Ultimately, your flux cored welders would continue to operate normally without having any performance issue.

However, those welders that have this system are quite more expensive than other machines.

8. Calculating Maintenance And Repair Expenses

Well, every investment contains the purchase cost, and the maintenance expense. The latter one is often overlooked by many welders. However, it is very essential to keep an eye on it.

The maintenance and repair expenses pretty much depends on the welder’s type and quality. The higher quality the machine is, the less maintenance and repair expenses they become.

To avoid these costs, a wise decision is to choose items from reputed brands only. Why? Because they have a wonderful warranty for their welders.

My Top Pick

Well, among my list, I would surely pick the YesWelder 250A MIG Pro as my top choice.

Basically, the machine has more than enough features for me to perform flux cored arc welding at ease.

It can generate a very wide range of output current (from 20 to 250 amperes). Its duty cycle is pretty high, also (60% at 250 amperes). The welder is versatile as well, with the ability to do multi-process.

All in all, no matter if you are new to welding or are an veteran welder, this YesWelder is a wonderful item for your workplace.

Conclusion

That’s it for now.

I hope my list has inspired you to choose the best flux cored welder for your workplace in 2021.

Whenever there is an update on the list, I will make sure you are the first one to know.

Thank you for your reference.

Reference

- Best Flux Core Welders – Reviews and Top Picks. Weld Guru. Retrieved January 30th, 2021.

- 5 Best Flux Core Welders fors 2021 Budget & Pro. Welding Insider. Retrieved January 30th, 2021.