TIG Welding Mild Steel is very similar to TIG Welding of other materials.

However, there are certain aspects that you need to pay close attention to.

As there is very limited content about this topic, we decide to prepare this accurate Introductory Course by covering:

- Setup and preparation for TIG Welding Mild Steel.

- Some tips and tricks for TIG Welding Mild Steel

Without further ado, let’s dive right in!

Shielding Gas for TIG Welding Mild Steel

1. Shielding Gas Type for TIG Welding Mild Steel

Just like TIG Welding Stainless Steel or other materials, Pure Argon is the ultimate TIG gas option to go for TIG Welding Mild Steel.

Other alternatives, including gas mixture of Argon with Hydrogen or Nitrogen, are NOT recommended.

2. Setting Gas Flow for TIG Welding Mild Steel

Setting proper gas flow is also very important for TIG Welding Mild Steel, and is based mainly on your cup size and welding conditions.

If you perform MIG Welding Mild Steel with a bigger cup, or when you do it outside with windy conditions, you will need to increase your gas flow.

The optimal range of gas flow for TIG Welding Mild Steel is from 5 – 25 cfh.

The following table indicates the proper gas flow based on your cup size:

Table 1 – Gas Flow Setting based on Cup Size for TIG Welding Mild Steel

| Tungsten diameter | Cup Size | Gas Flow |

| 1/16’’ | 4, 5, 6 | 5 – 15 cfh |

| 3/32’’ | 6, 7, 8 | 8 – 20 cfh |

| 1/8’’ | 6, 7, 8 | 8 – 25 cfh |

Also, when TIG Welding Mild Steel, it is recommended to place your weld in an Argon bath.

Sometimes, you can purge the weld with a filler gas.

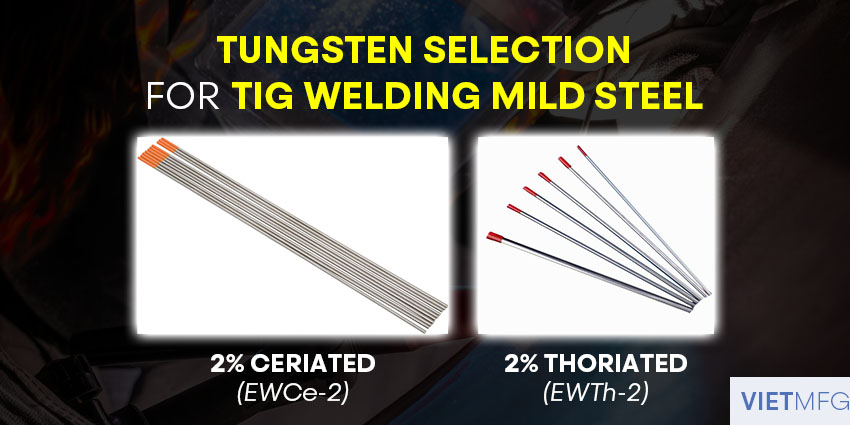

Best Tungsten for TIG Welding Mild Steel

For TIG Welding Mild Steel, use an ORANGE tungsten electrode (2% Ceriated Tungsten, EWCe-2), or RED tungsten electrode (2% Thoriated Tungsten, EWTh-2).

These types of tungsten electrode are suitable as TIG Welding Mild Steel does not require high amperage settings.

Also, most TIG Welding Mild Steel projects involve thin material, or sheet metal, which works fine with ORANGE tungsten.

Remember to sharpen your tungsten to a fine point before applying in TIG Welding projects.

Top Option for TIG Welding Mild Steel Filler Rod

Top option for TIG Welding Mild Steel Filler Rod is ER309 Stainless.

ER309 filler rod works well on hot rolled mild steel and does not cause porosity.

This type of filler rod is typically applied for TIG welding critical points in the power generation industry, which features a lot of welding stainless to mild steel.

Welder Setup for TIG Welding Mild Steel

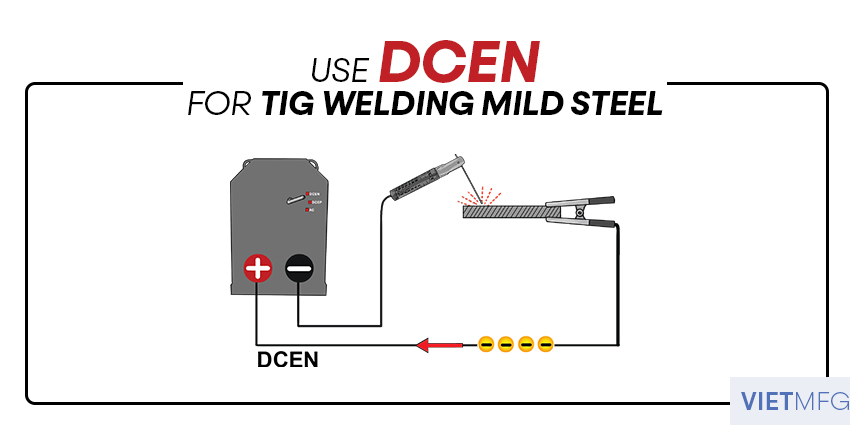

1. Polarity Setting for TIG Welding Mild Steel

Among 3 polarity options for TIG Welding (DCEN, DCEP and AC), it is best to go with DCEN – Direct Current Electrode Negative – for TIG Welding Mild Steel.

DCEN polarity puts more heat into the workpiece, which results in a deeper penetration weld.

2. TIG Torch Type for TIG Welding Mild Steel

When it comes to TIG Torch for TIG Welding Mild Steel, there are 2 options:

- Air-cooled TIG Torch.

- Water-cooled TIG Torch.

Air-cooled TIG Torch for TIG Welding Mild Steel

Air-cooled option is suitable for those who are having a budget constraint.

However, air-cooled torches generate a lot of wasted heat and require many breaks from time to time during your TIG Welding sessions of Mild Steel.

After 10 – 15 minutes of welding, you will start to feel the heat from the torch handle, which suggests break time.

Water-cooled TIG Torch for TIG Welding Mild Steel

If you hate to have breaks in between welding sessions, then you should go with water-cooled torches for TIG Welding Mild Steel.

This water-cooled option requires extra equipment – the water cooler.

Thus, it is a more expensive option.

Water-cooled TIG torches allow you to perform welding operations in a continuous way (without breaks), which boost up your productivity.

Table 2 – A short comparison between air-cooled and water-cooled TIG Torches

for TIG Welding Mild Steel.

| Criteria | Air-cooled | Water-cooled |

| Price | Affordable | Expensive |

| Productivity | Low | High |

| Other | Wastes heat | Requires water cooler |

3. Amperage Settings for TIG Welding Mild Steel

Your amperage settings must be based on your material thickness and joint types.

Higher amperage helps melting your filler rod faster into the weld puddle.

You should play around with it to determine the most suitable amperage setting for your TIG Welding Mild Steel projects.

The following table shows some recommended settings for TIG Welding Mild Steel, based on material thickness and joint types.

Table 3 – Recommended amperage settings for TIG Welding Mild Steel

| Joint Type | Material Thickness | Amperage Setting |

| Butt Weld | 1/16’’ | 50 – 80 |

| 3/32’’ | 80 – 110 | |

| 1/8’’ | 85 – 120 | |

| 3/16’’ | 125 – 200 | |

| 1/4’’ | 225 – 300 | |

| 1/2’’ | 300 – 400 | |

| Lap Weld | 1/16’’ | 60 – 90 |

| 3/32’’ | 90 – 120 | |

| 1/8’’ | 100 – 140 | |

| 3/16’’ | 150 – 200 | |

| 1/4’’ | 250 – 325 | |

| 1/2’’ | 325 – 425 | |

| Corner Weld | 1/16’’ | 50 – 80 |

| 3/32’’ | 80 – 110 | |

| 1/8’’ | 85 – 120 | |

| 3/16’’ | 150 – 200 | |

| 1/4’’ | 225 – 300 | |

| 1/2’’ | 325 – 425 | |

| Fillet Weld | 1/16’’ | 60 – 90 |

| 3/32’’ | 90 – 120 | |

| 1/8’’ | 110 – 154 | |

| 3/16’’ | 175 – 225 | |

| 1/4’’ | 250 – 325 | |

| 1/2’’ | 325 – 425 |

Some Tips and Tricks for TIG Welding Mild Steel

1. Use TIG High-Frequency Start on your Welder

With High-Frequency Start Function, your arc will be automatically formed when your TIG torch is 1 inch away from the workpiece.

This is very beneficial for TIG Welding Mild Steel as it can prevent your tungsten from touching the weld puddle and be contaminated.

You can save a lot of time from having to replace tungsten many times, as well as be more cost-effective.

2. Make use of Gas Pre-Flow and Post-Flow

Using pre-flow and post-flow settings for TIG Welding Mild Steel is very handy, especially when it comes to weld thin materials.

While pre-flow gas provides protection before you strike and form the arc, post-flow feature helps keep the weld puddle safe for a predetermined time after you terminate your arc.

3. Do NOT use AC Waveform Controls

You should not do anything with the AC Waveform Control on your welder when you TIG weld Mild Steel.

For Mild Steel, you should always stick with DCEN.

AC Waveform Controls function is suitable for TIG Welding Aluminum or Magnesium.

4. Utilize Stick Welder for TIG Welding Mild Steel

TIG Welder can be an expensive choice.

Thus, if you have a Stick Welder on hand, you can simply convert it to perform TIG Welding Mild Steel to save cost.

The conversion requires only an air-cooled TIG torch and an extra Argon bottle.

This is how you convert a Stick Welder to a TIG Welder:

- Firstly, switch polarity setting to DCEN.

- Secondly, attach your air-cooled TIG torch to the electrode holder.

- Last but not least, hook your Argon bottle to a gas flow regulator and connect it to your welder.

5. Keep your Mild Steel clean with Sanding Disc

Keeping your base material – Mild Steel – clean is a critical part of TIG Welding.

If you do it incorrectly, you will see the filler rod does not flow and stick properly into the weld puddle.

Thus, make use of a sanding disc to keep your base material, especially at the joint area, clean.

Conclusion

You have finished all the basics in our introductory course about TIG Welding Mild Steel.

After reading, we hope you have had a clear picture of what to prepare for such a welding process.

Reference

- Welding Principles and Practices (5th Edition) – McGraw Hill Education. Edward R.Bohnart. [2017]

- How to Set Up a TIG Welder for Mild Steel? Welding Mastermind. Retrieved September 24th 2020.

- Welding Mild Steel Sheet Metal | TIG Time. Youtube (Weld.com channel). Retrieved September 24th 2020.

- TIG Welding Mild Steel. Youtube (WeldFever channel). Retrieved September 24th 2020.